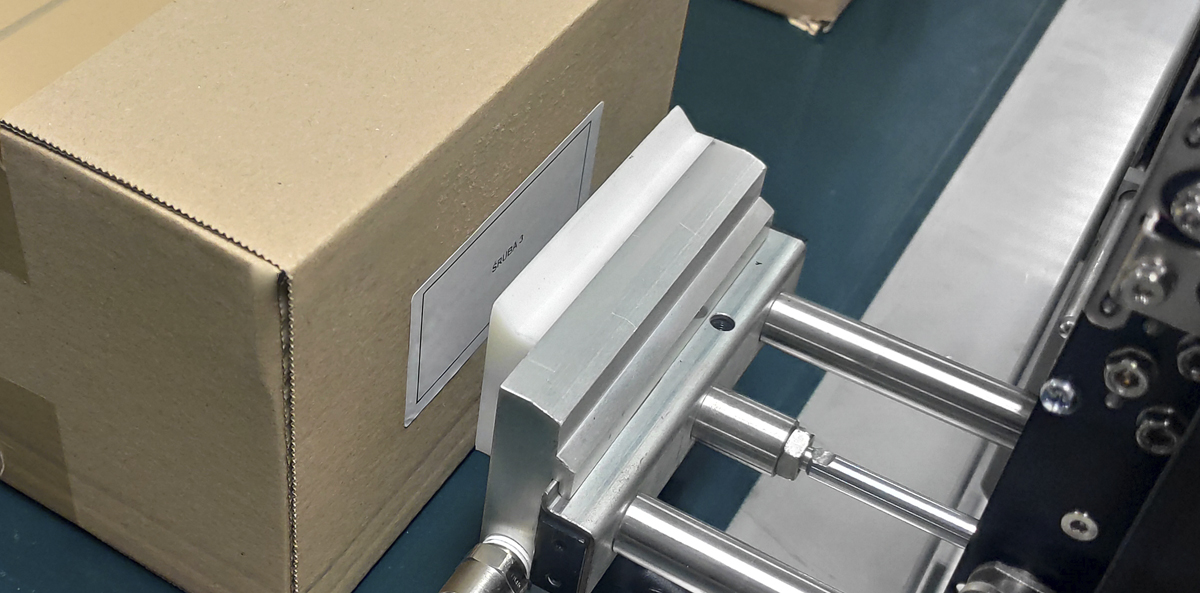

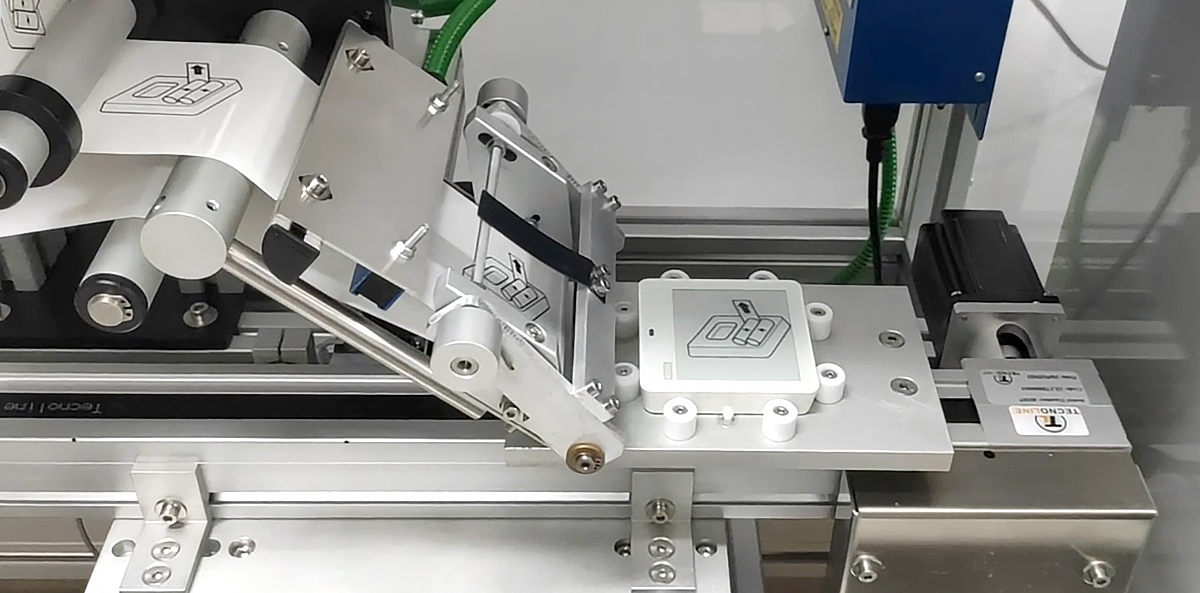

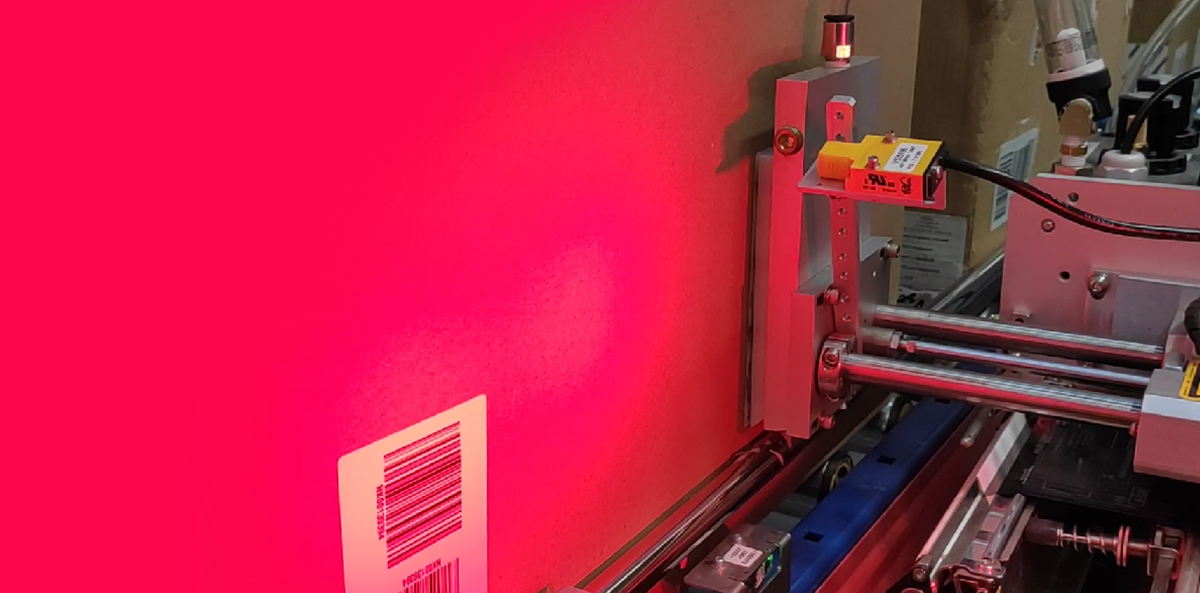

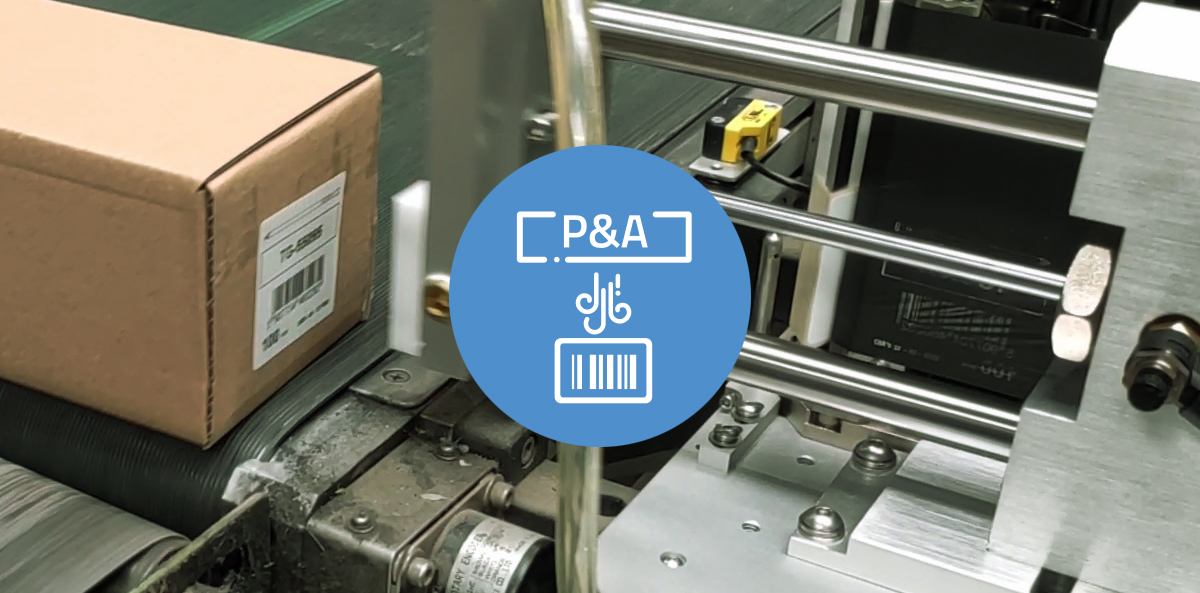

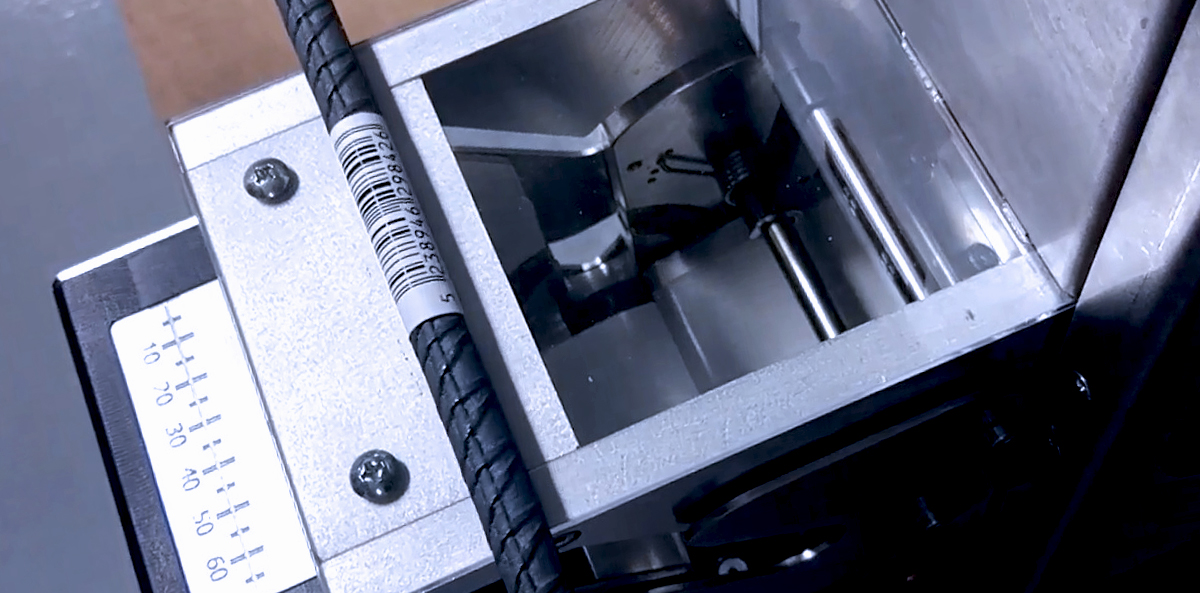

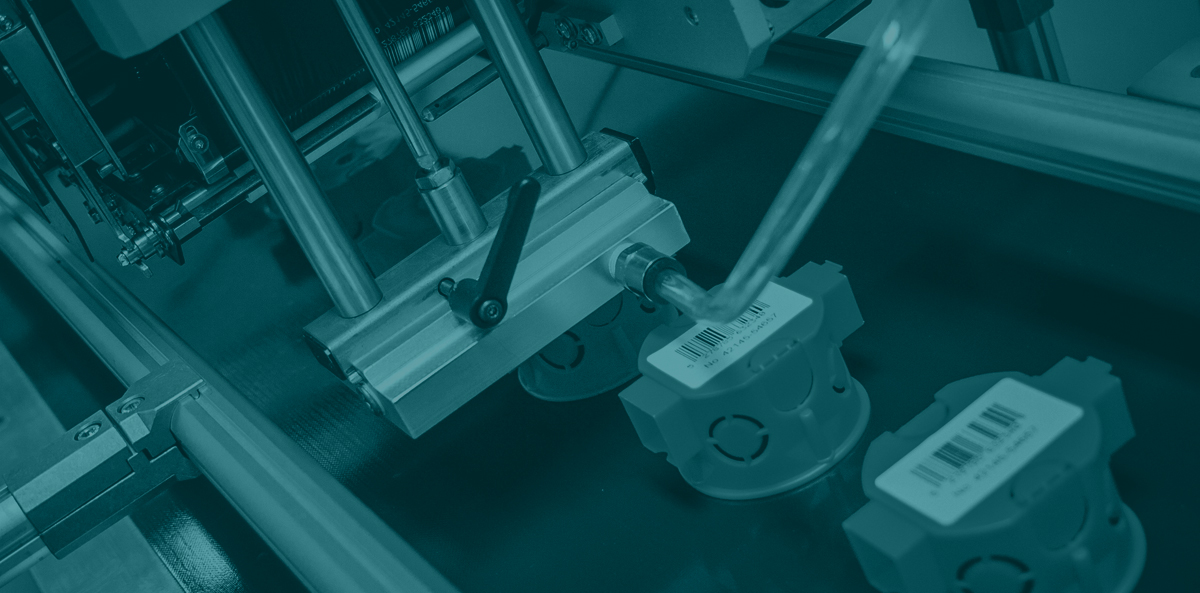

Label applicator for home appliance companies

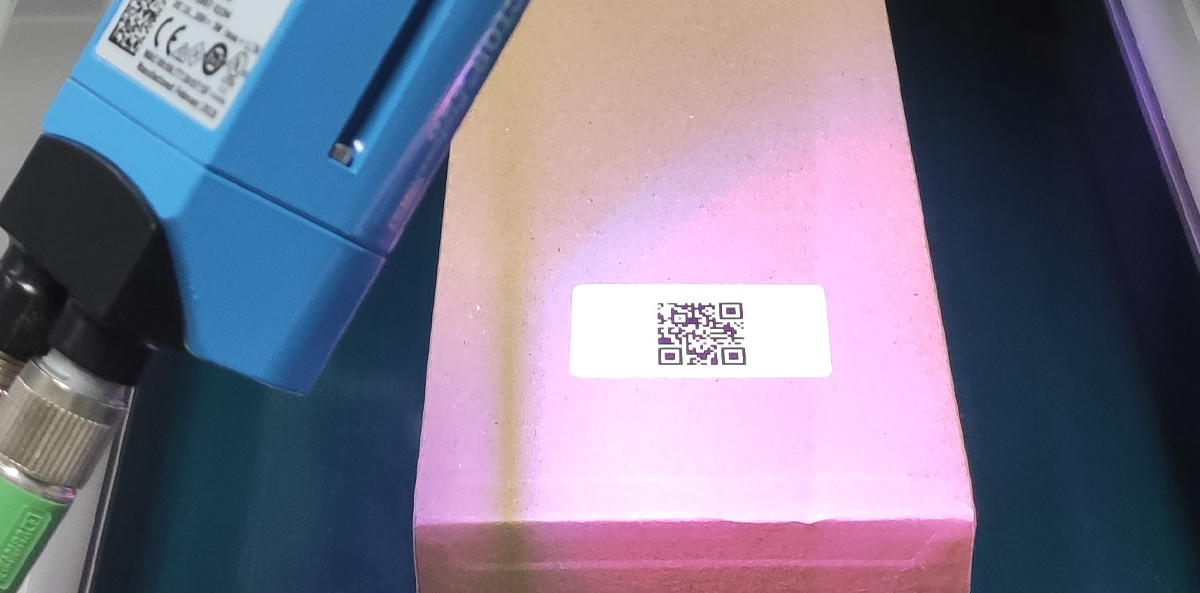

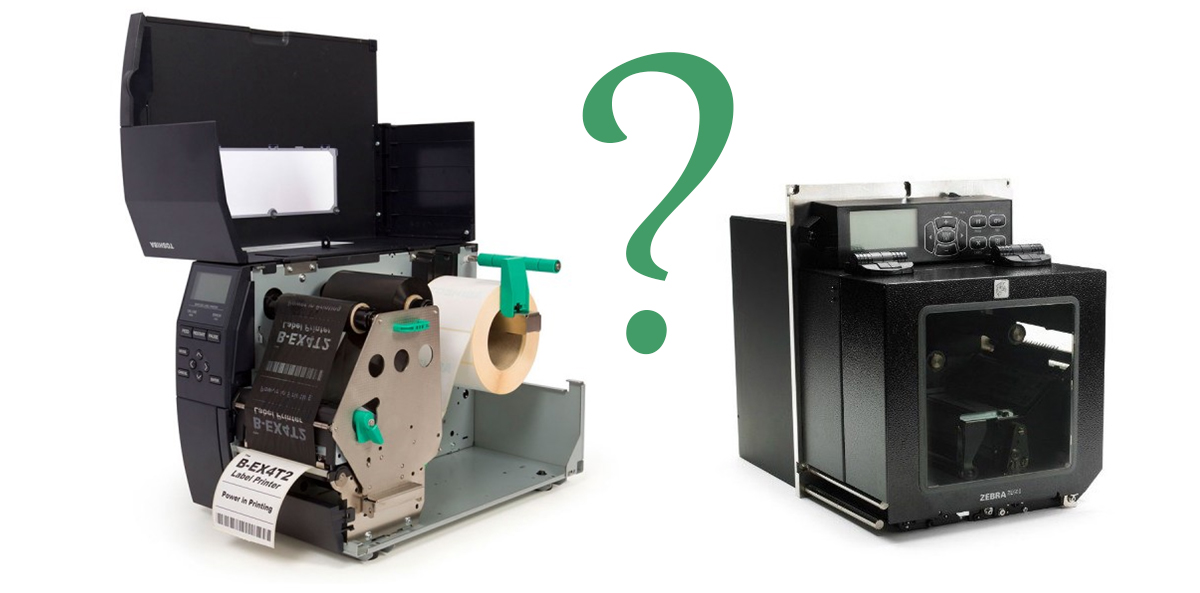

Manufacturers of appliances in the white goods sector apply labels of different types to their products. These can be marketing labels, promotional labels, labels containing technical and service data, nameplates, […]