IntraBot Fork autonomous forklift truck

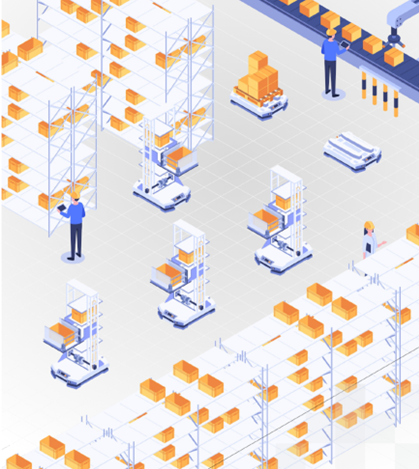

The IntraBot Fork autonomous forklift truck is designed for transporting pallets, totes, and wheeled containers. The autonomous forklift AGVs/AMRs move independently along the designated warehouse or production floor routes from the loading station to the unloading station. They autonomously pick up pallets from the floor and transport them to the (...)