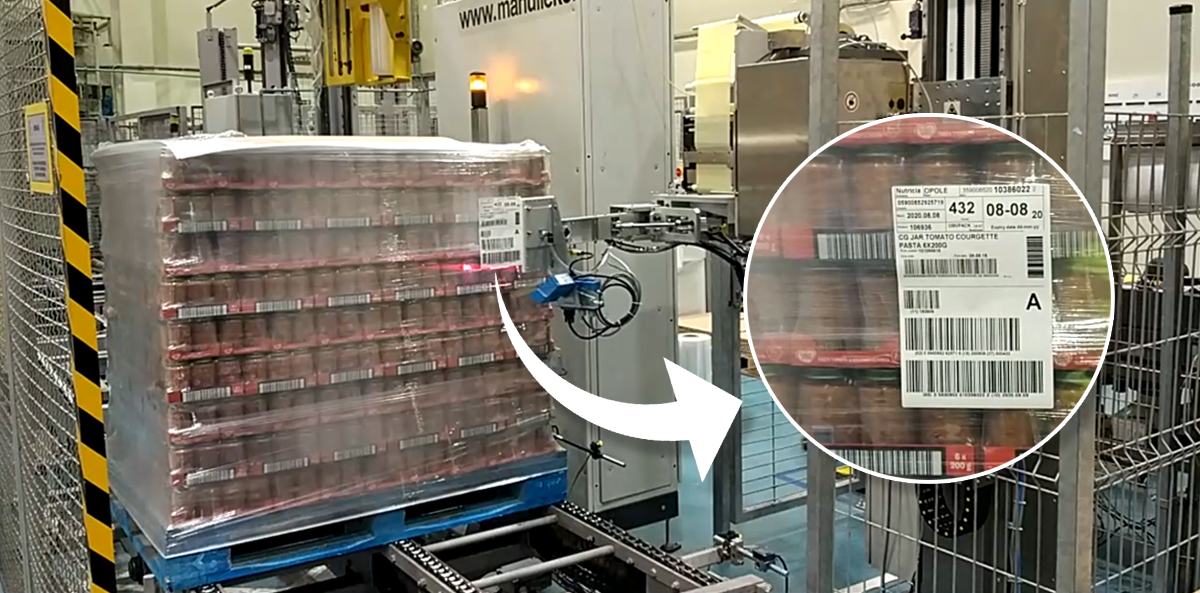

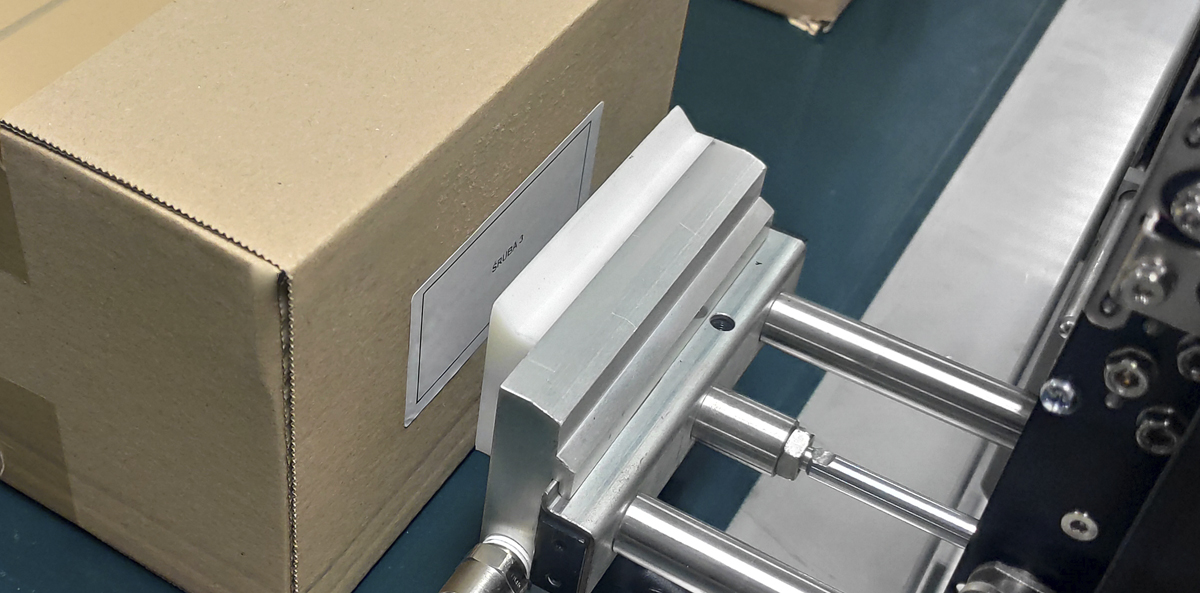

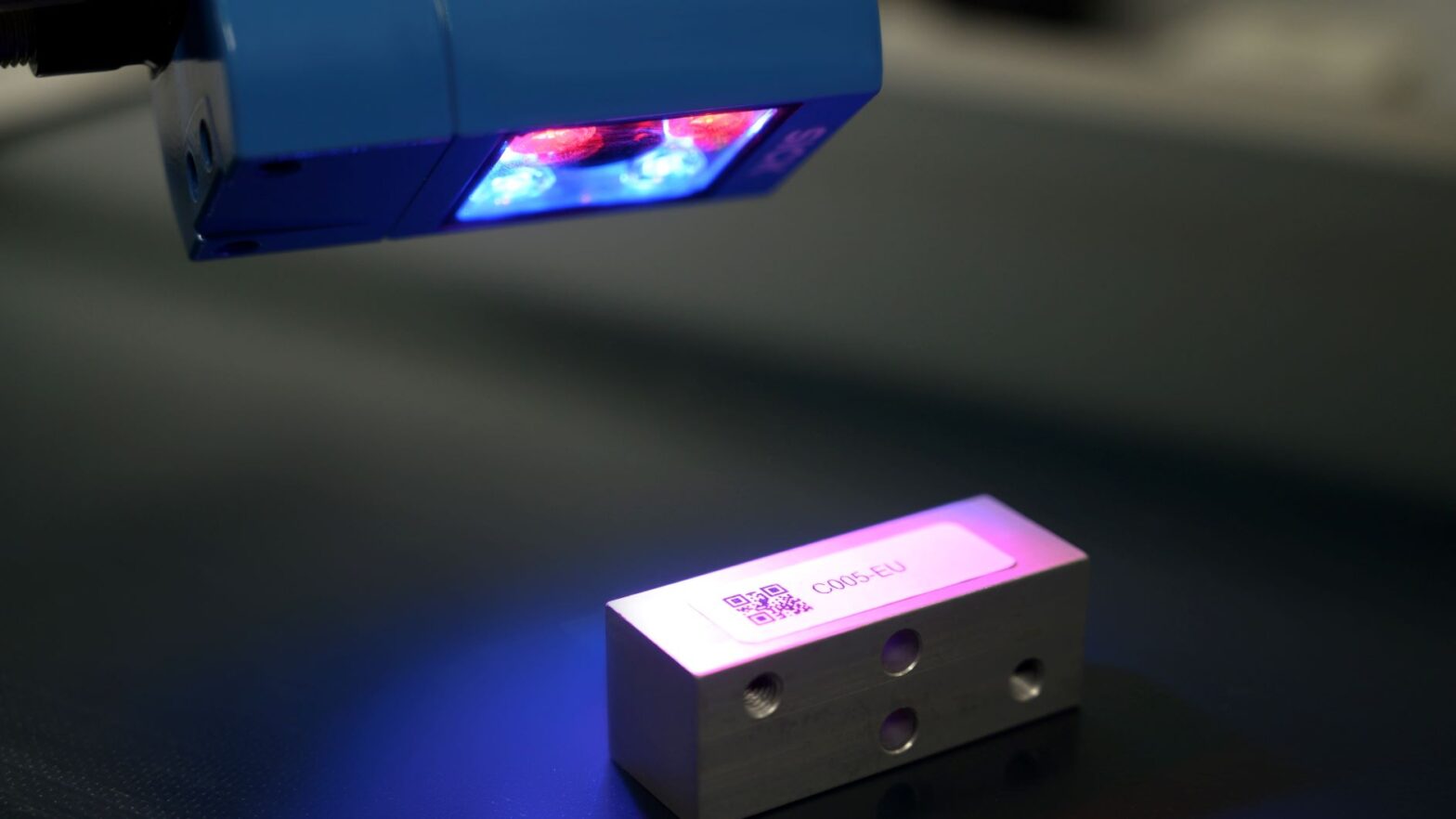

Print and apply

The printing and application devices (Print&Apply) - used for printing variable information on the label and label application to the product or its packaging. They are customized to operate and be installed directly on the production lines. The printing and application devices consist of a printing module based on thermal (...)