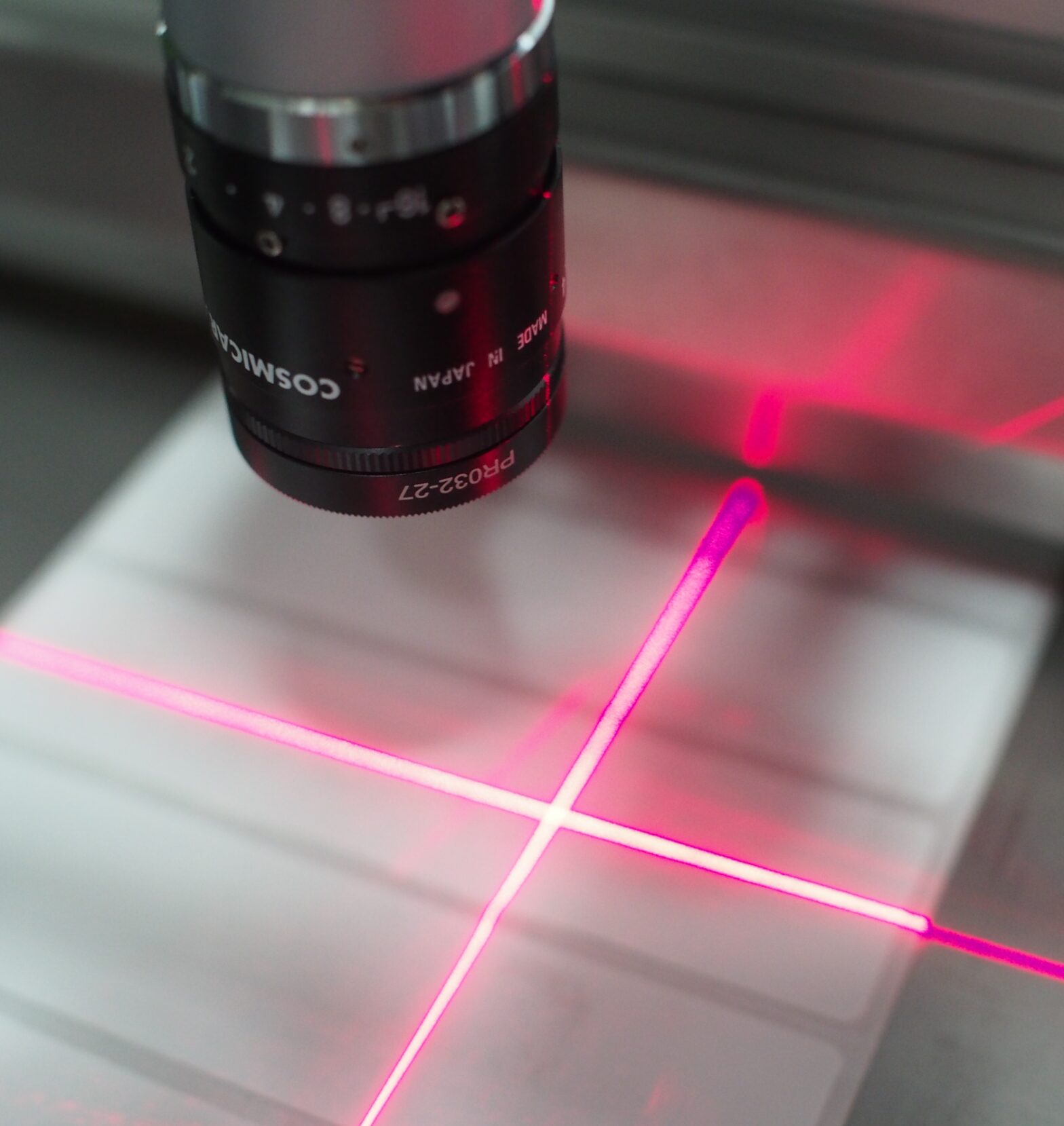

Fixed scanners, smart cameras and vision sensors

Vision and scanning systems using sensors, smart cameras and fixed industrial readers perform quality control in the production department or warehouse. They enable automatic inspection of products moving on production lines in various industries. The task of the quality control system is to separate products that are not made in (...)