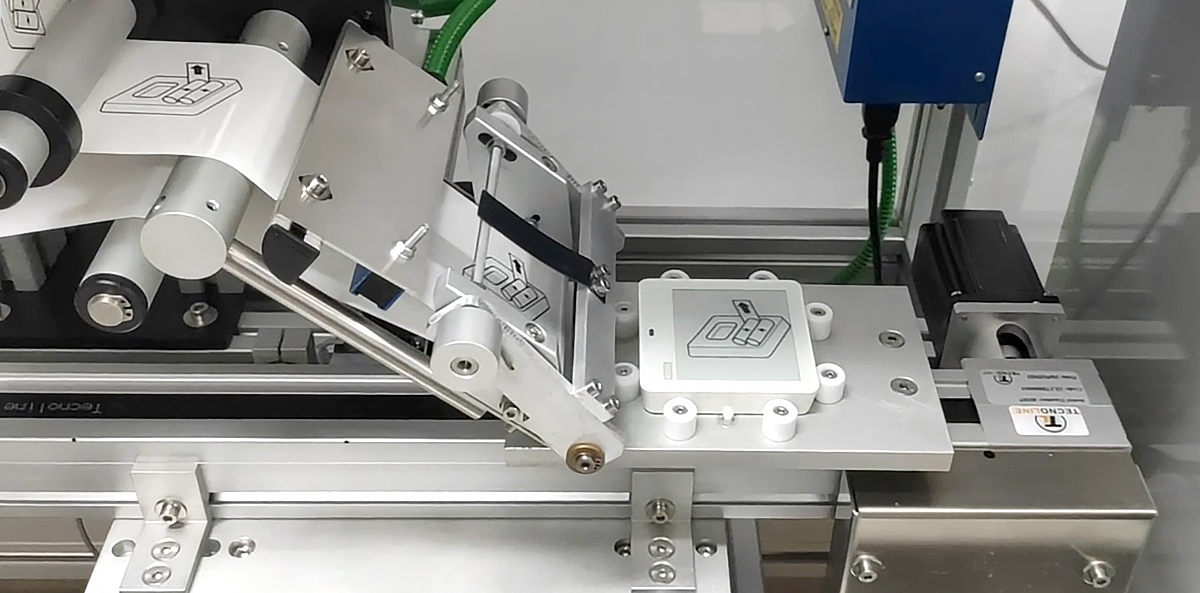

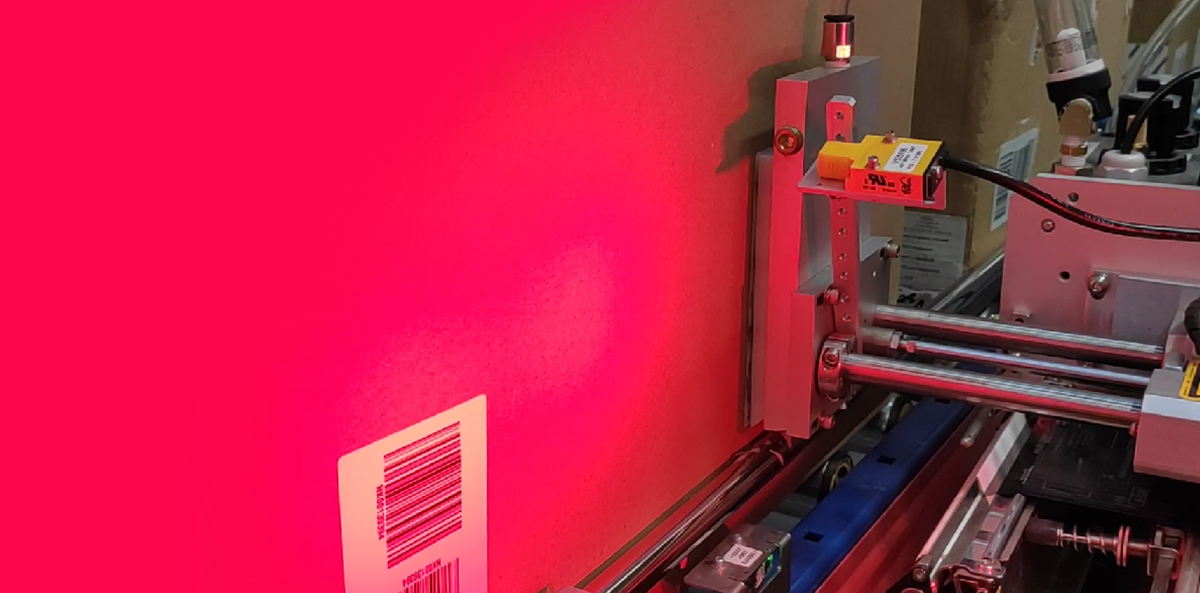

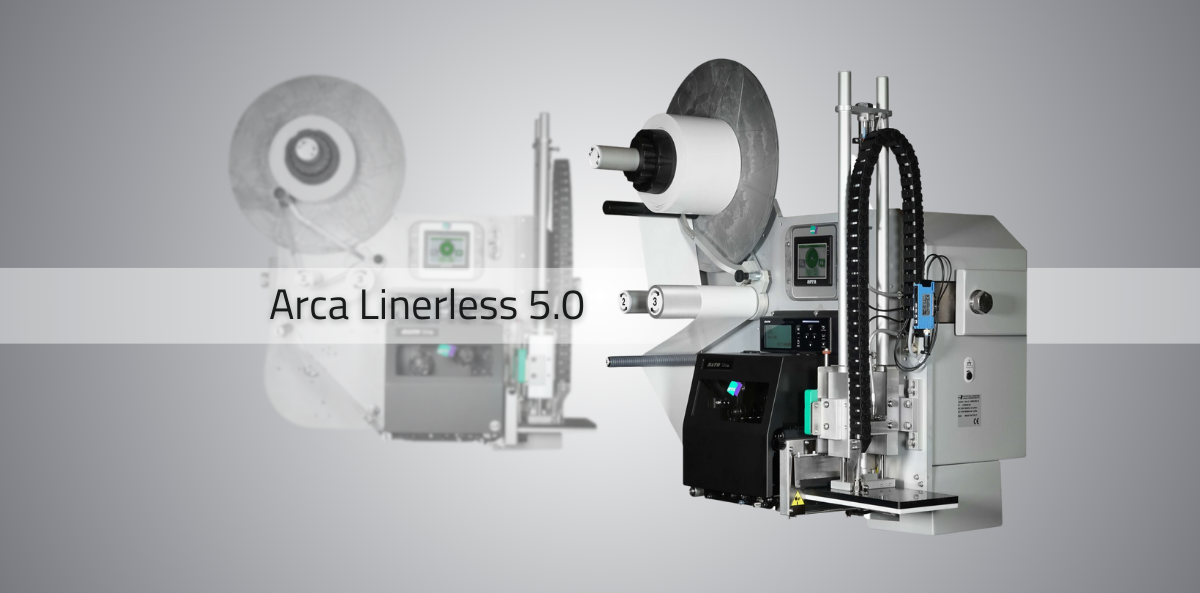

Linerless labels and their application. Meet the next-generation eco-friendly and cost-effective printing and application device!

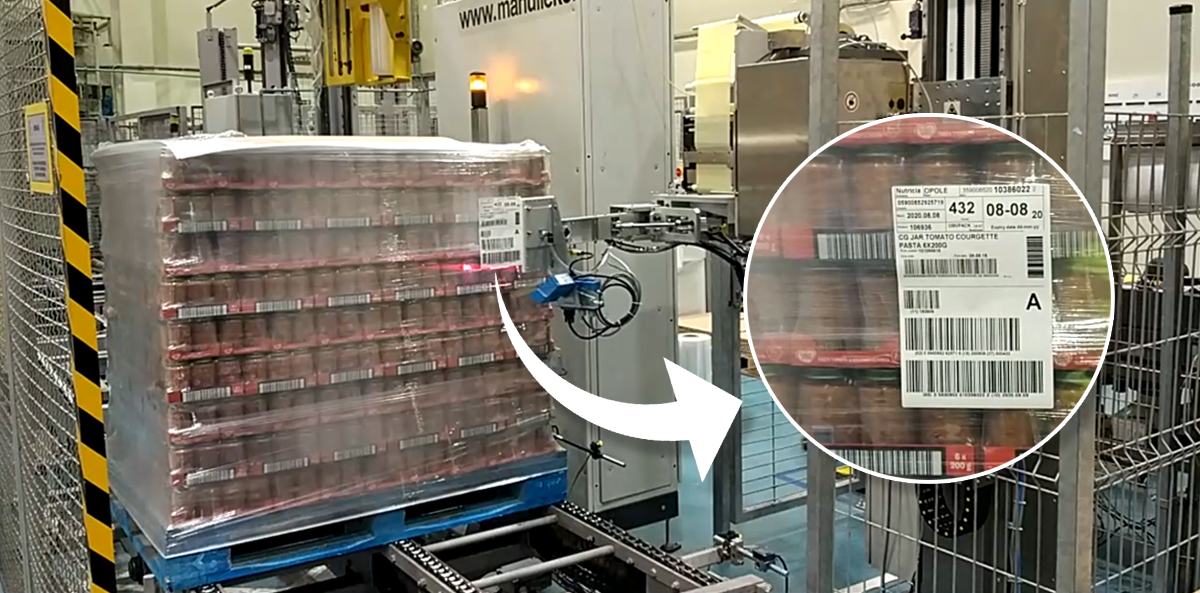

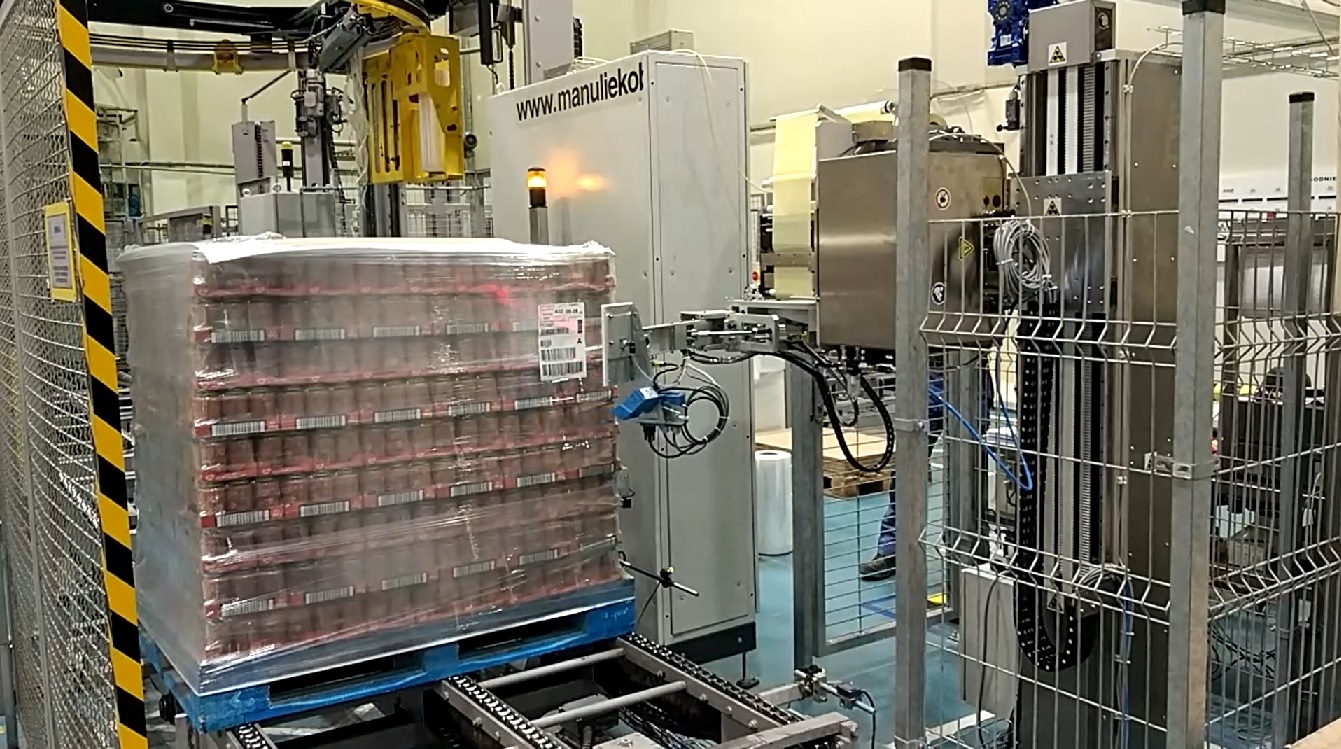

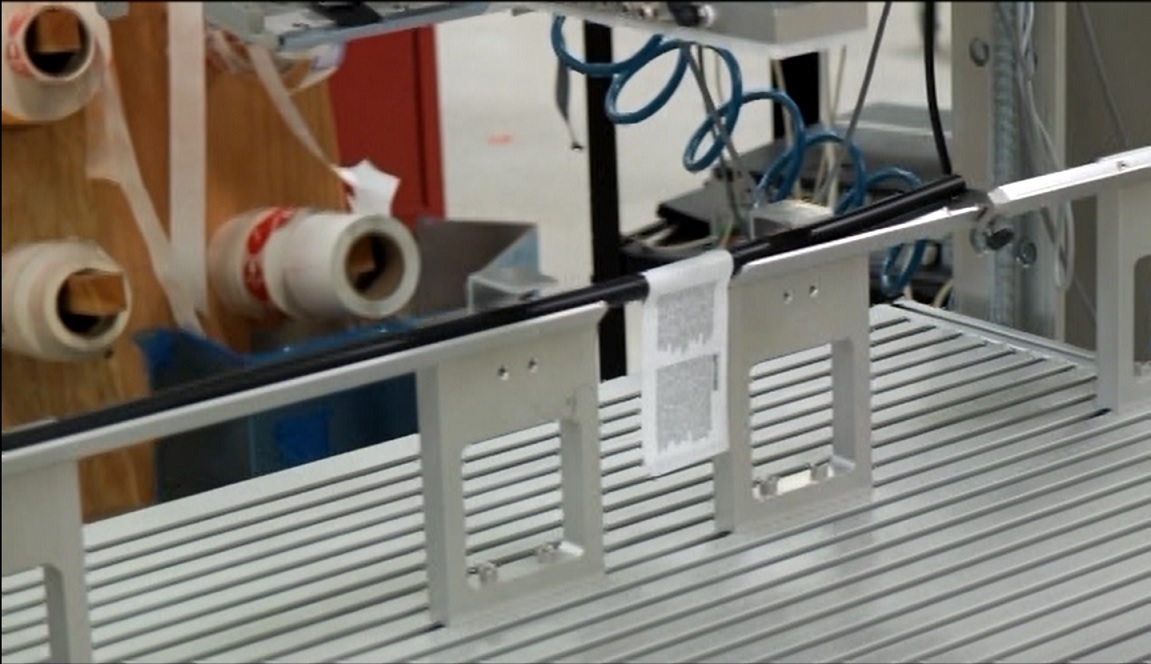

Companies are increasingly looking for solutions that allow them to simultaneously optimize their operating costs and reduce the environmental impact of their operations. In response to these needs, Etisoft has […]