What does a vision system consist of?

The intensive development of industrial markets makes more and more companies invest in vision systems. The use of specialized cameras on production lines is dictated by higher quality requirements, the […]

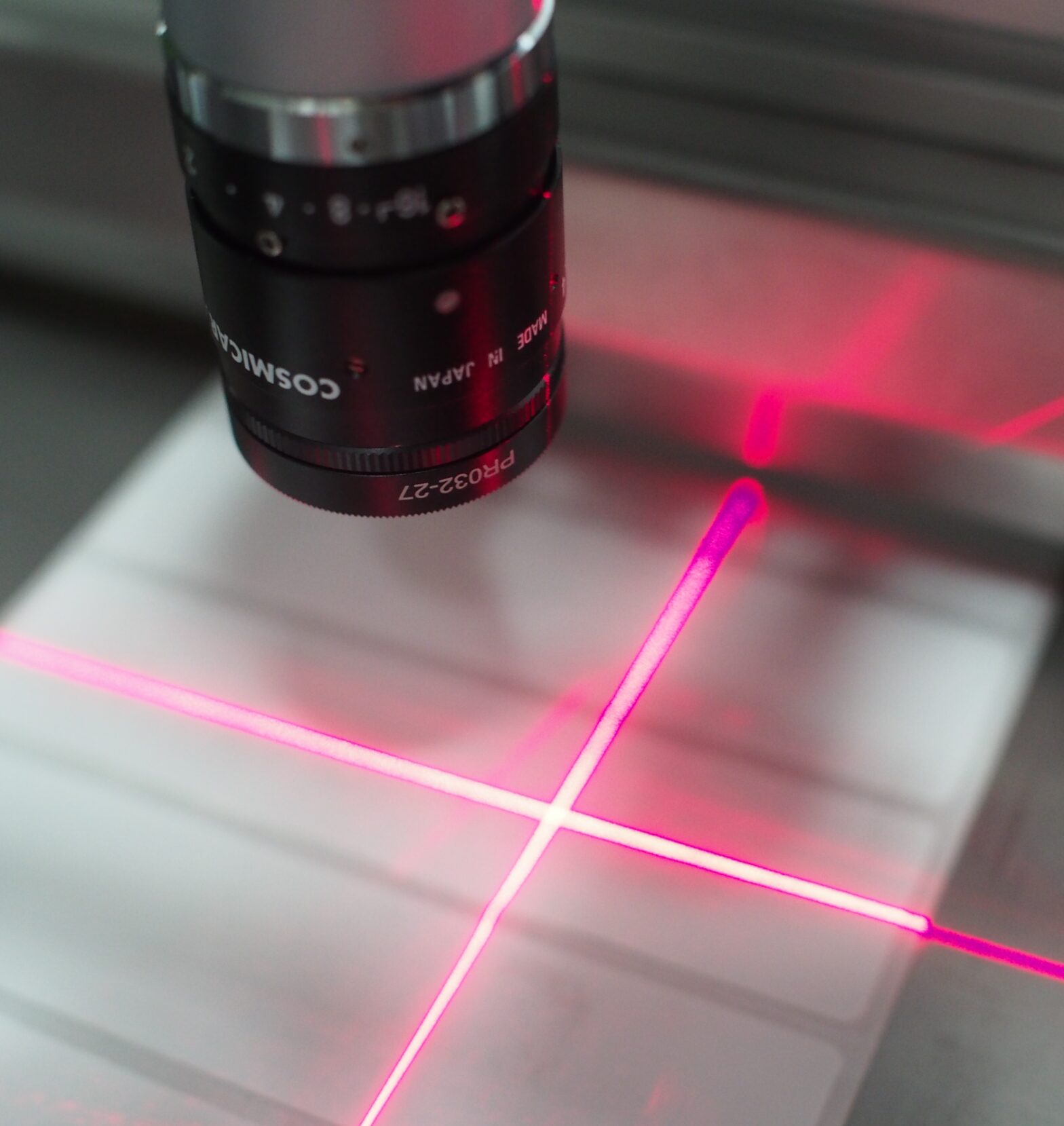

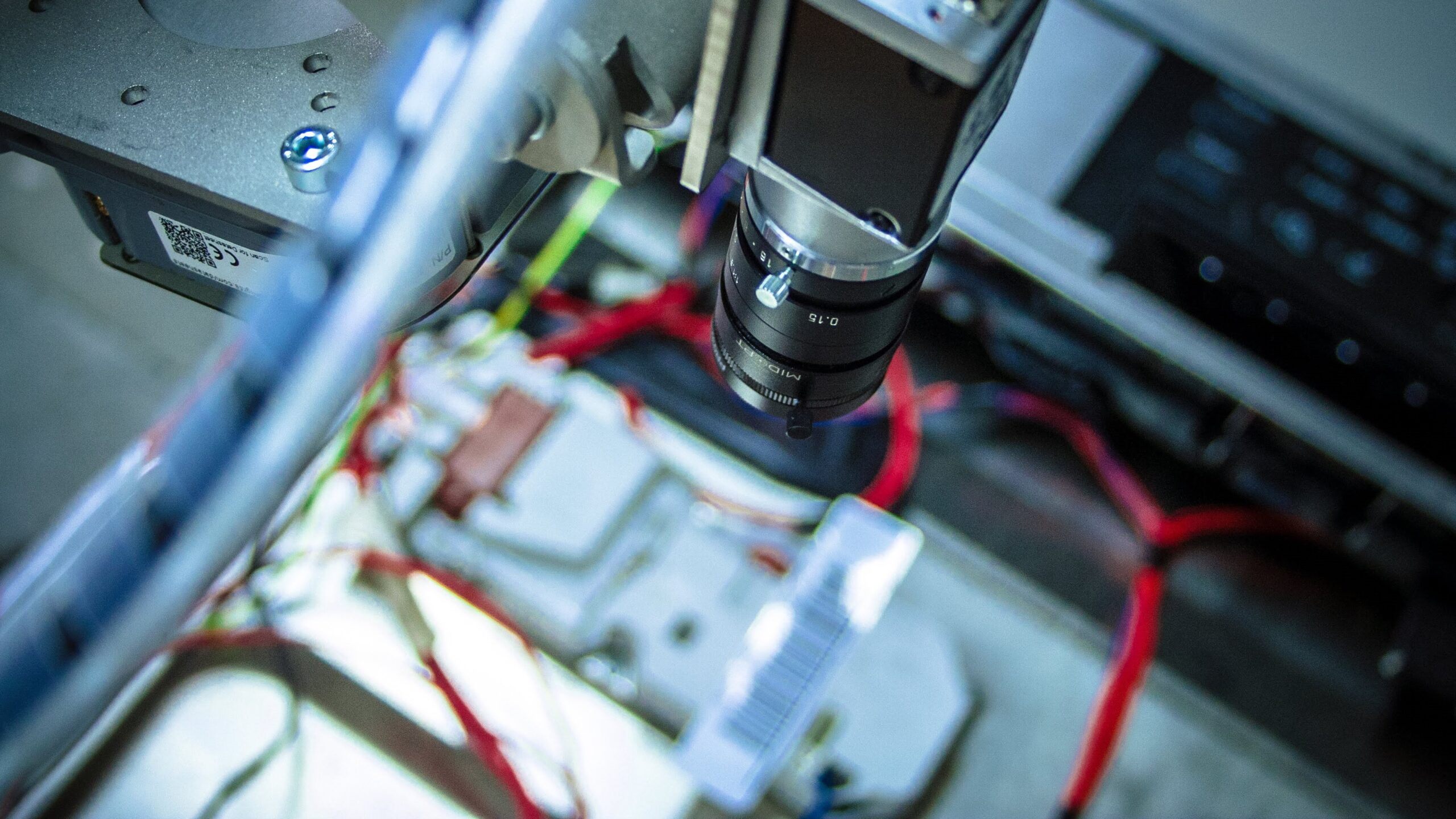

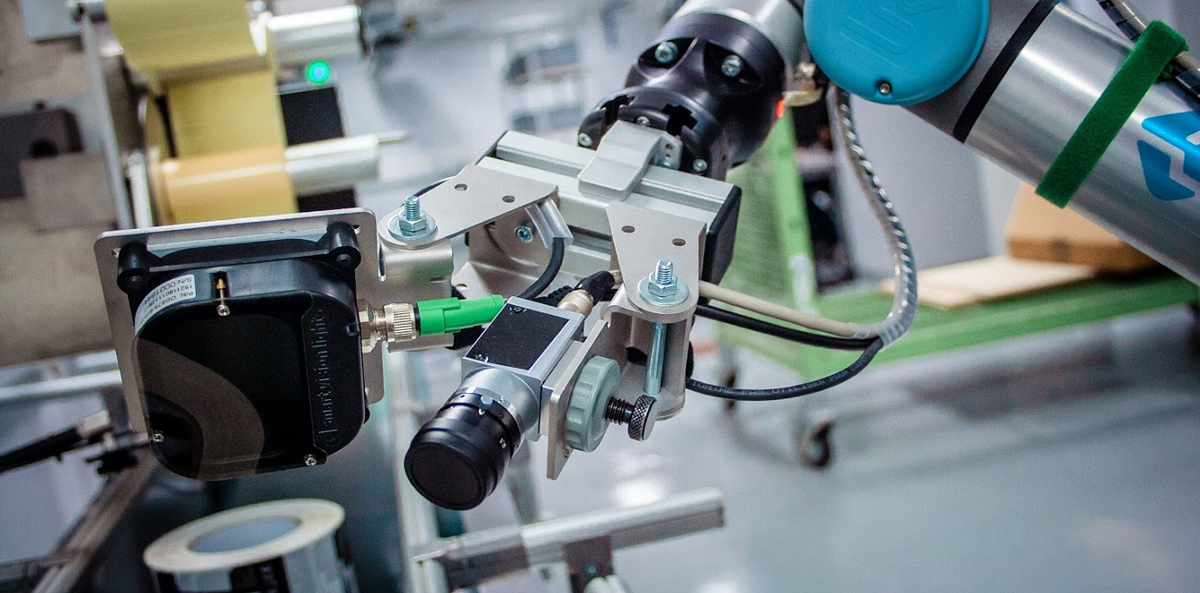

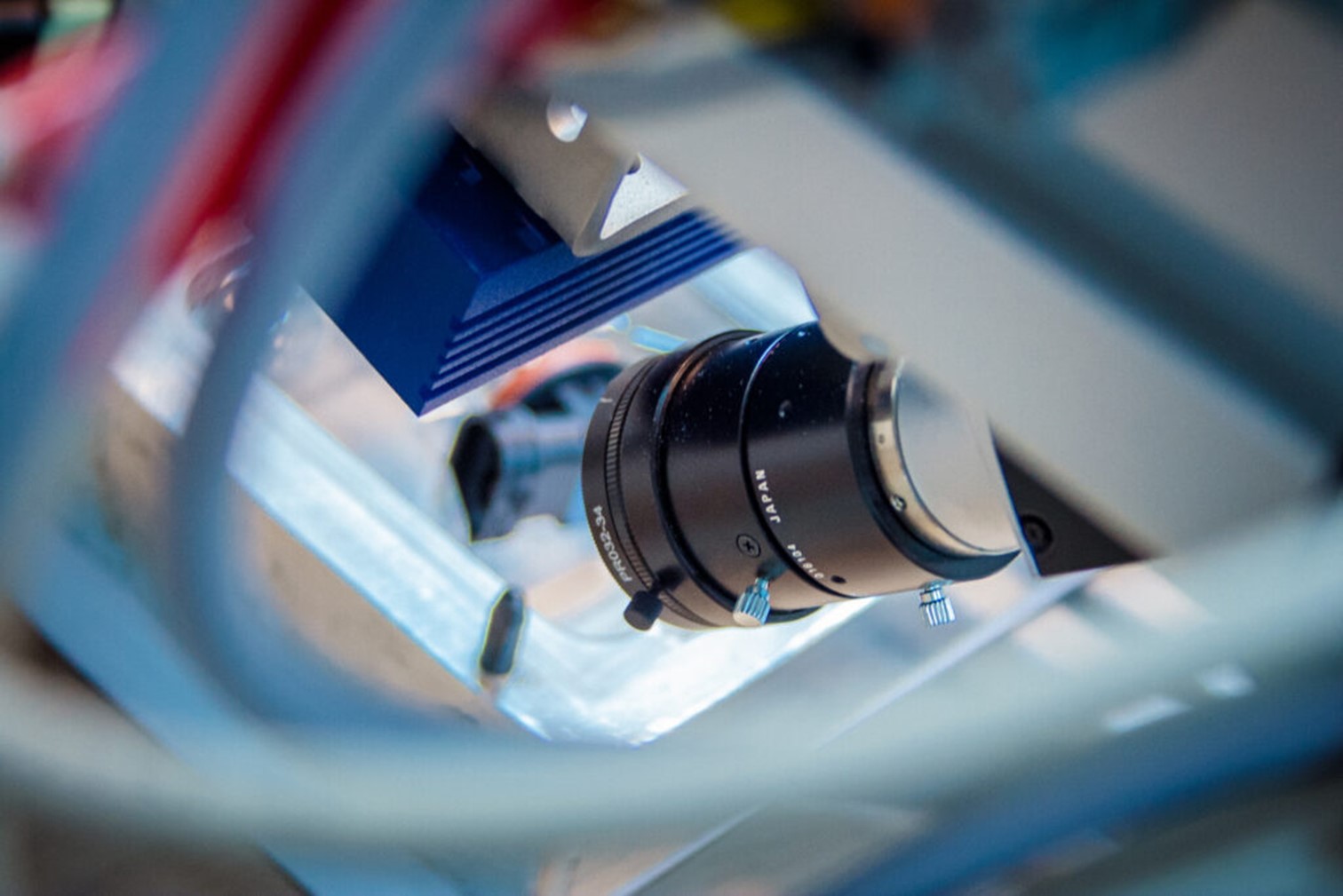

Advanced vision systems are designed to meet individual customer needs. Our automatic quality control systems are complete solutions, based on industry standards and using modern technologies and devices. We develop and adapt systems to individual requirements, using 2D, 3D, linear cameras and multi-camera systems as well as special lighting techniques adapted to the specificity of the project. The systems are based on high-quality cameras and software that repeatably analyses 2D or 3D images and compares them with saved standards and deviation values. The modular structure of the system and open architecture allows you to implement any system operating logic and thus reflect and implement even complex verification, control or inspection processes. Each of our systems can be integrated with both automation systems (production line PLC controllers, homing systems, casepackers, etc.) and robotics systems (vision system installed on the robotic arm, vision system controlling the robot’s operation), to ensure greater flexibility and with IT systems, to be as maintenance-free as possible.

Application

WE PRODUCE, DESIGN AND IMPLEMENT

Together with Etisoft Smart Solutions we design and supply automated quality control systems based on machine vision.

We ensure:

Our vision systems are comprehensive solutions based on industry standards and using modern technologies and top-quality devices. We develop and adjust solutions to individual customer needs using 2D, 3D, linear and multi-camera systems as well as special lighting techniques adapted to the specific project. Depending on the needs and project requirements we use classic algorithms or Deep Learning technology.

The modular construction of the system and open architecture make it possible to implement any logic of system operation and thus reflect and implement even complicated processes of verification, control, or inspection. Each of our systems can be integrated with both automation systems (production-line PLCs, reference positioning systems, case packers etc.) and robotic systems (vision system mounted on a robotic arm, vision system controlling the work of a robot) for greater flexibility, and with IT systems to make it as maintenance-free as possible.

The system detects nonconformities at assembly stations resulting from incorrect robot operation or human error. The cameras smoothly record images in a way adapted to the moving production line, whereas the software analyses the correct assembly of semi-finished and finished goods. The position of all elements, the presence of all components after assembly, and correctness of the connection of the cable harness are checked, missing screws, washers and seals are detected. Upon detection of a nonconformity, signalling or automatic removal of the product from the production line takes place. The advantages of the vision system for quality control of assembly and connections are, among others, as follows:

Vision control systems for production quality control make it possible to quickly verify shapes, dimensions and colours of elements cut, cast from the mould. Algorithms precisely measure details and detect errors such as thickening, deformation of shapes, missing mounting holes. The vision system signals deviations from the set standard, and in case of a repeated serial error it can stop the machine. Advantages of the system:

A vision system that checks the correct positioning of the product in the unit packaging. The developed algorithms determine the position of goods and signal their incorrect positioning. The software also recognizes when the wrong product manufactured on the same production line is placed in the packaging. The whole solution for inspection of correctness of packaging is integrated with the production line and can automatically stop it if an error has been detected. It prevents damage to the packaging, products or placing the wrong number of products in a collective packaging. Advantages of the system:

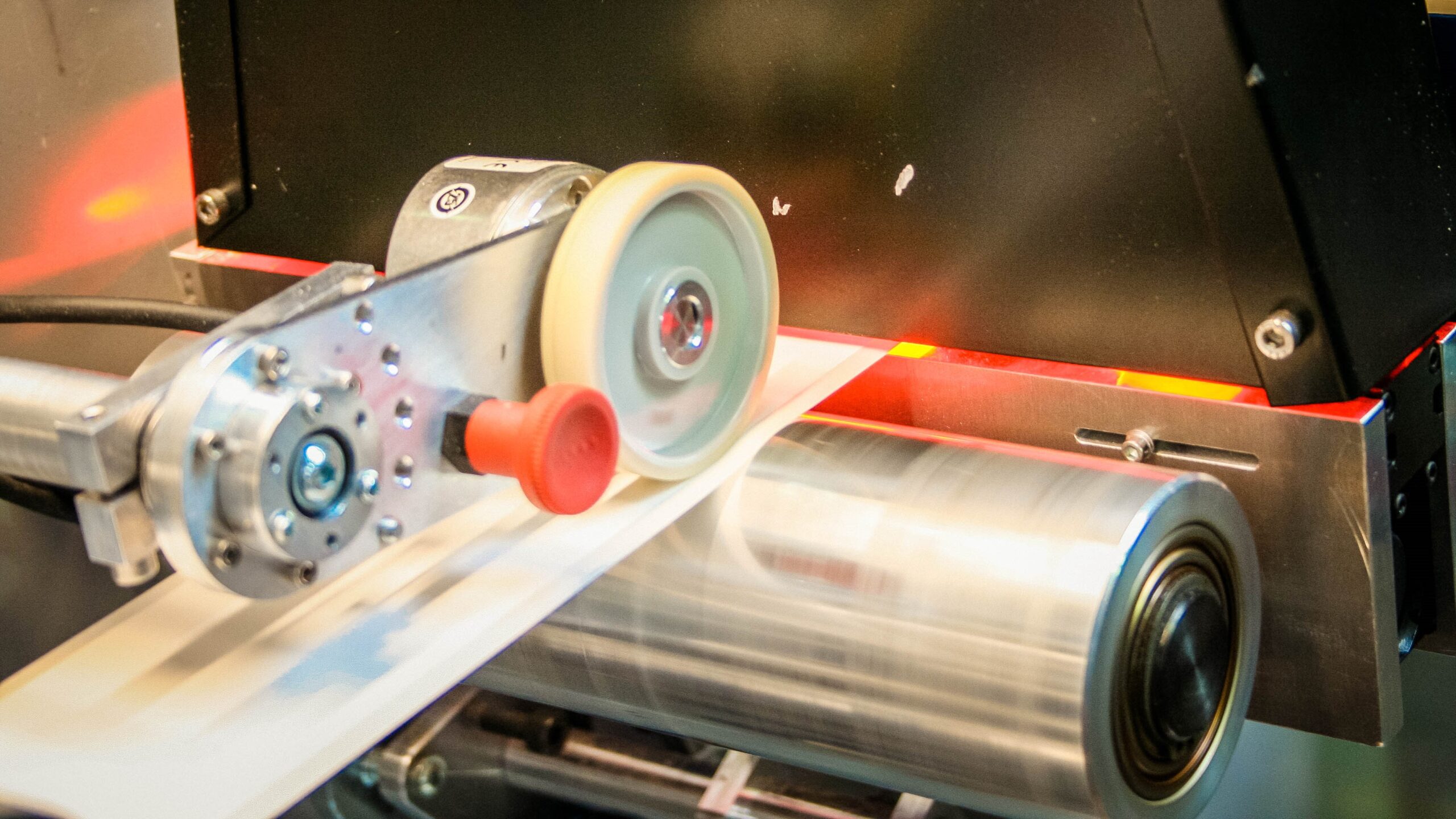

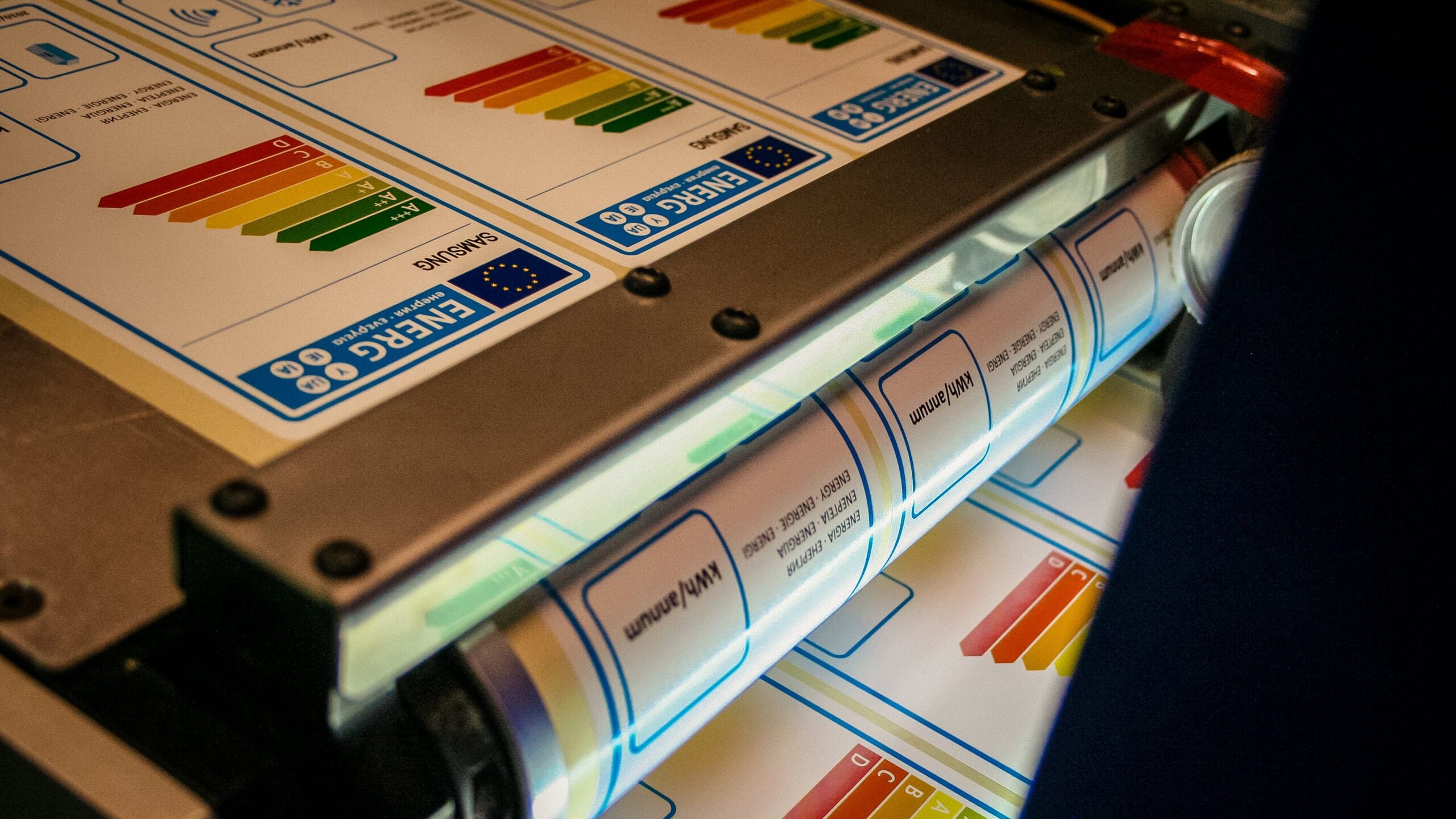

A system based on machine vision is intended for the verification of print quality and the detection of printing errors occurring during the printing of product labels. The system can be used in label printing centres in production halls – printshops. The software detects printing defects, ink blurring, thickening, deformation of shapes of iconography and signs. Defective labels are not used for labelling production on production lines. The printing quality control system can be adapted to various printing technologies, e.g., screen printing, thermal transfer, digital printing.

A vision system made up of cameras, sensors, and barcode readers, which is used for verification of data applied to the product at different stages of production. The system checks the position of the labels applied to the product, detects any missing labels in the given place of the product or packaging, verifies the correctness of the printed data, serial number, and barcodes. In the event of detection of a non-conformity, signalling or automatic removal from the production line takes place.

APPLICATIONS

In production:

In the warehouse:

SAFETY

Vision control systems integrated with the production line, industrial automation and MES systems constitute a key element of the quality management process. We will ensure safety at each stage of implementation and continuous supervision over the effectiveness and quality of operation of the implemented system.

We guarantee:

OUR IMPLEMENTATIONS

The recipients of our products are, among others, companies from the household appliances industry, suppliers of labels, factories of light technologies. Our portfolio includes implementations on productions lines of dishwashers, washing machines, dryers, refrigerators, and many others.

The intensive development of industrial markets makes more and more companies invest in vision systems. The use of specialized cameras on production lines is dictated by higher quality requirements, the […]

After reading the first part of the article you already know what the automated quality control looks like in the context of the analysis of customer needs and what business […]

In order to stay ahead in the competitive industrial environment, companies more and more meticulously track and control all the elements of the production process using Machine Vision solutions. This […]

Quality departments in manufacturing companies face a lot of challenges. Some of these can be met by implementing machine vision systems. However, it is not easy to design and implement […]

The presented solution is used for automatic visual inspection of bonded components and verification of assembly accuracy by the machine. The objective of the project was to shorten the duration […]

Entrepreneurs more and more frequently purchase machines for process automation, realising that even the best employees sometimes make mistakes or overlook something important in the process. Meanwhile, a well-designed and […]

One year ago, we implemented a new marketing strategy. Among other things, our company has been rebranded and our new logo emphasises our inventiveness and professionalism. How has the implementation […]

Machine vision system and artificial intelligence. The problem of frequent product changes – can it be solved with AI?

See the effects of the session carried out in our interiors where, while conducting our own production and warehouse processes, we use Industry 4.0 solutions offered by Etisoft Smart Solutions. […]

Customer requirements regarding parameters of the purchased products are getting higher and higher, therefore manufacturers are putting increasing emphasis on quality control. However, the fact is that 100% quality control […]

At the final stages of production, the incorrect position in which products are placed in the packaging becomes a frequent problem. The correct arrangement of products in the final packaging […]

The vision system designed by Etisoft Smart Solutions has been deployed at one of our customers to verify correctness of packing and picking unit packagings in packages. How does this […]

The human eye, in spite of being almost a perfect tool, sometimes experiences worse moments. It can be tired or ill. In case of repeated activities, our ability to see […]

Polish industry still depends on the solutions of “the third industrial revolution” and “shaman knowledge” of its employees. How can it be changed? The Evertiq portal devoted to the electronics […]