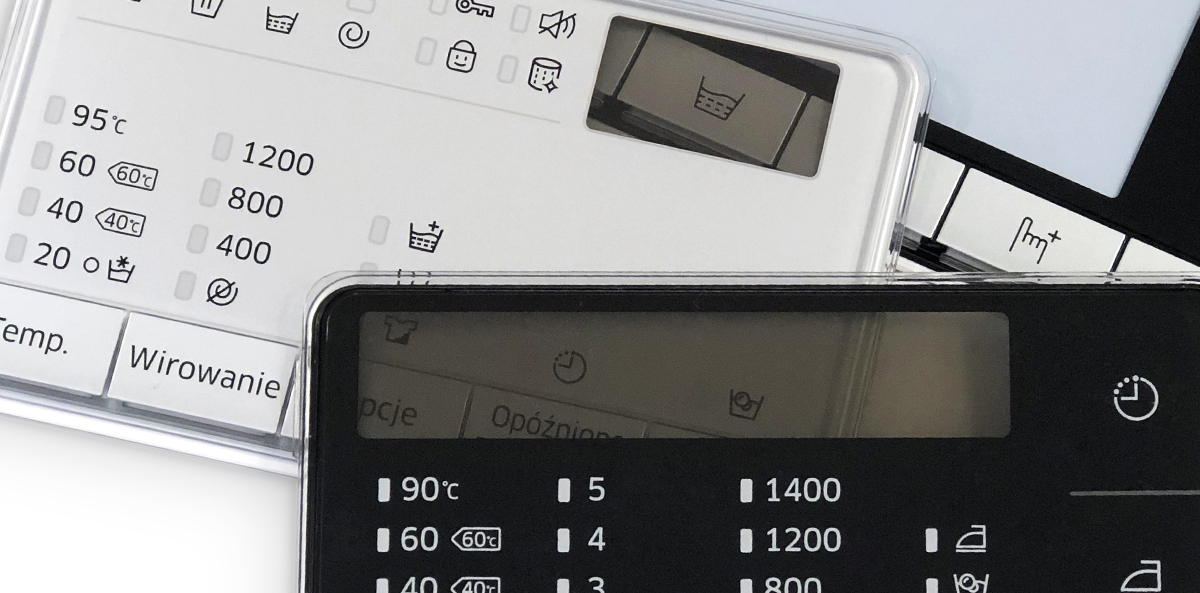

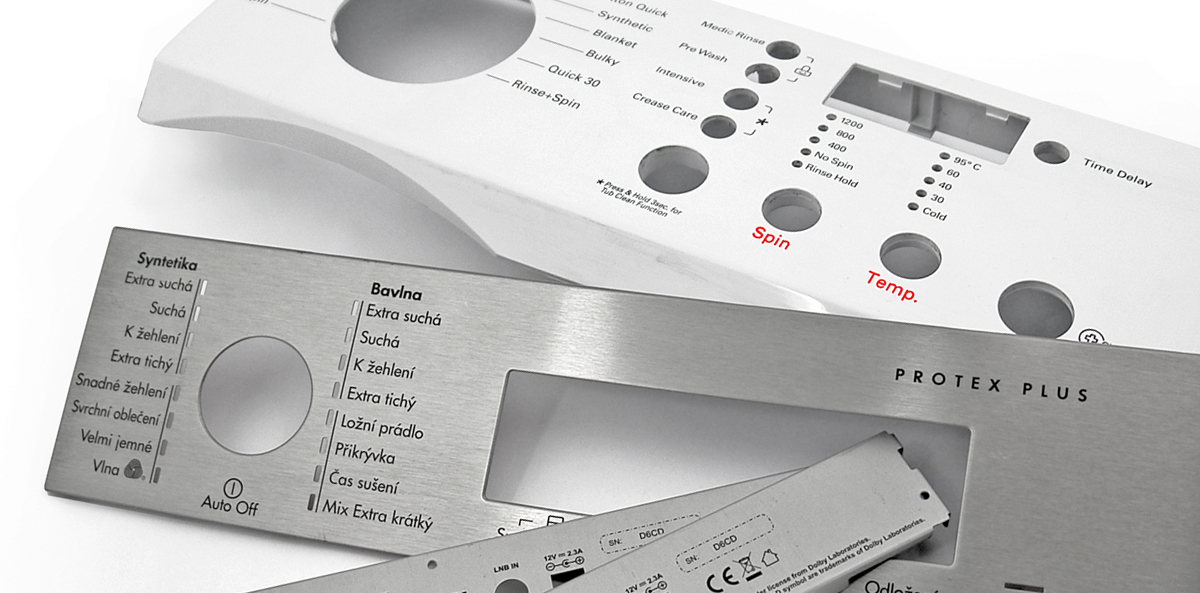

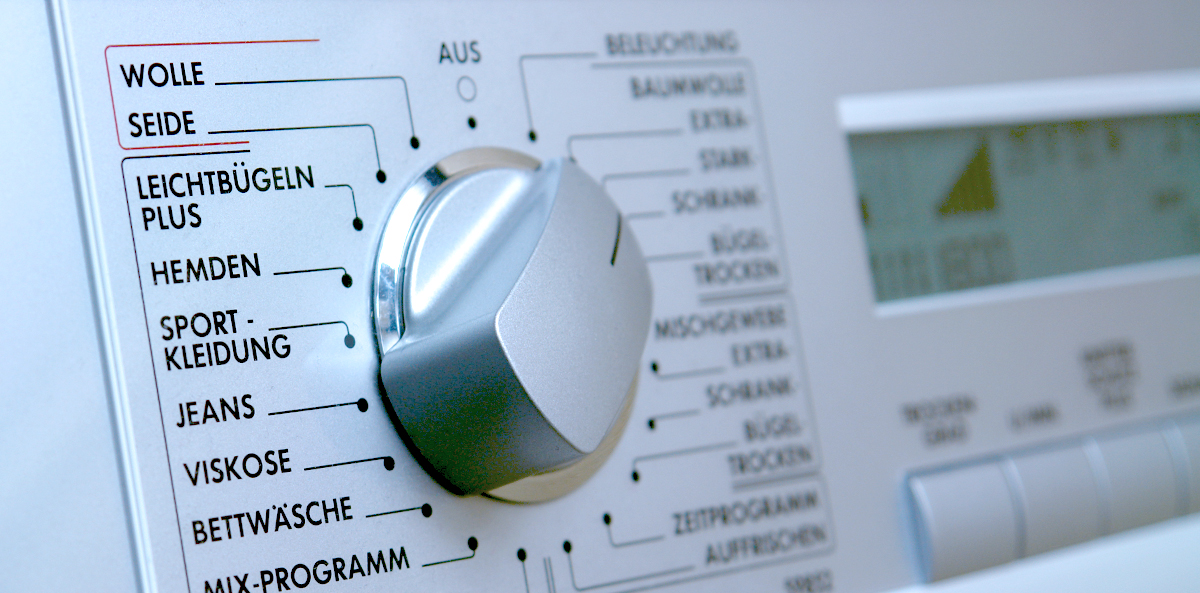

Control panels – why screen printing is the best choice for their production?

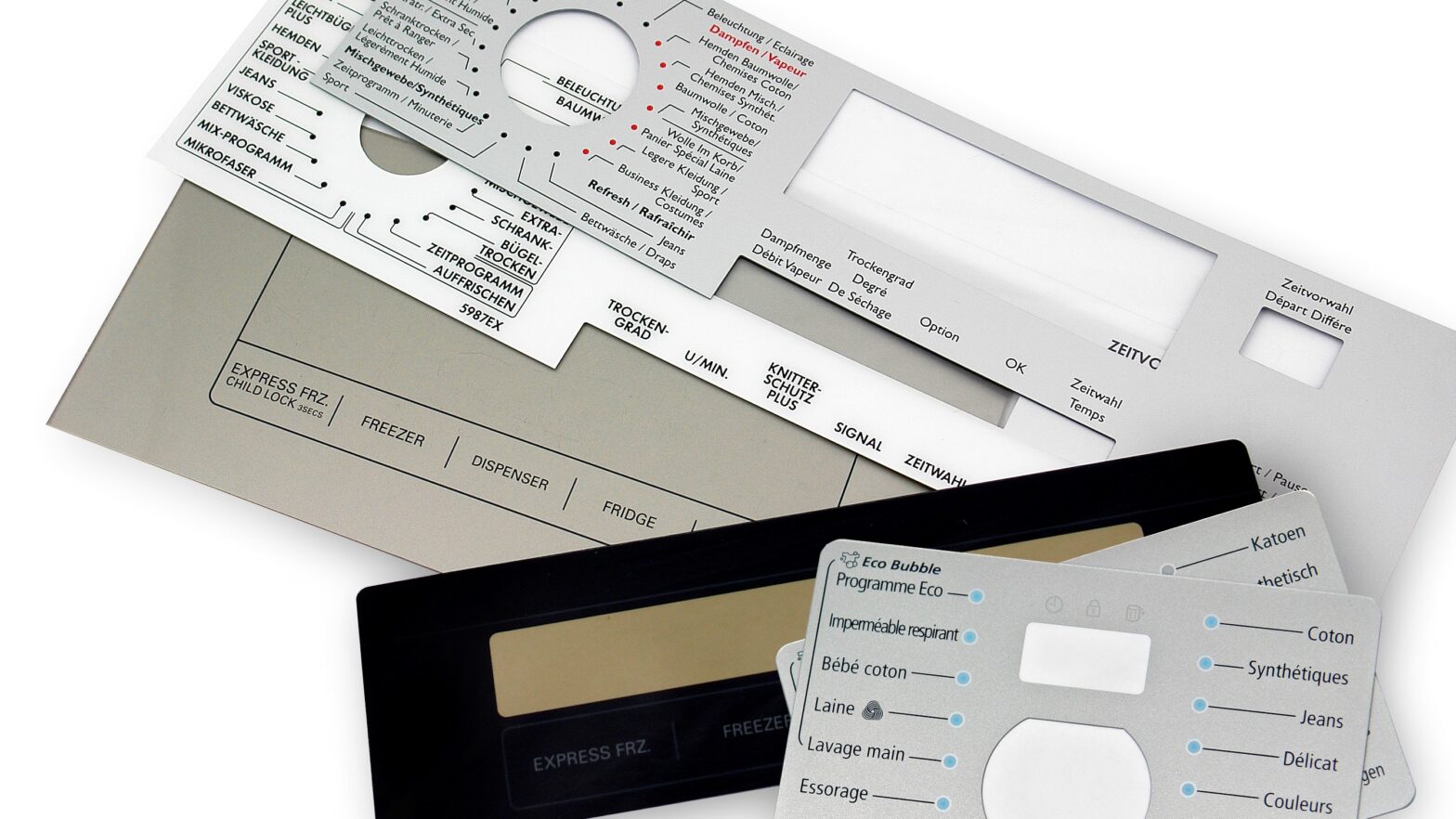

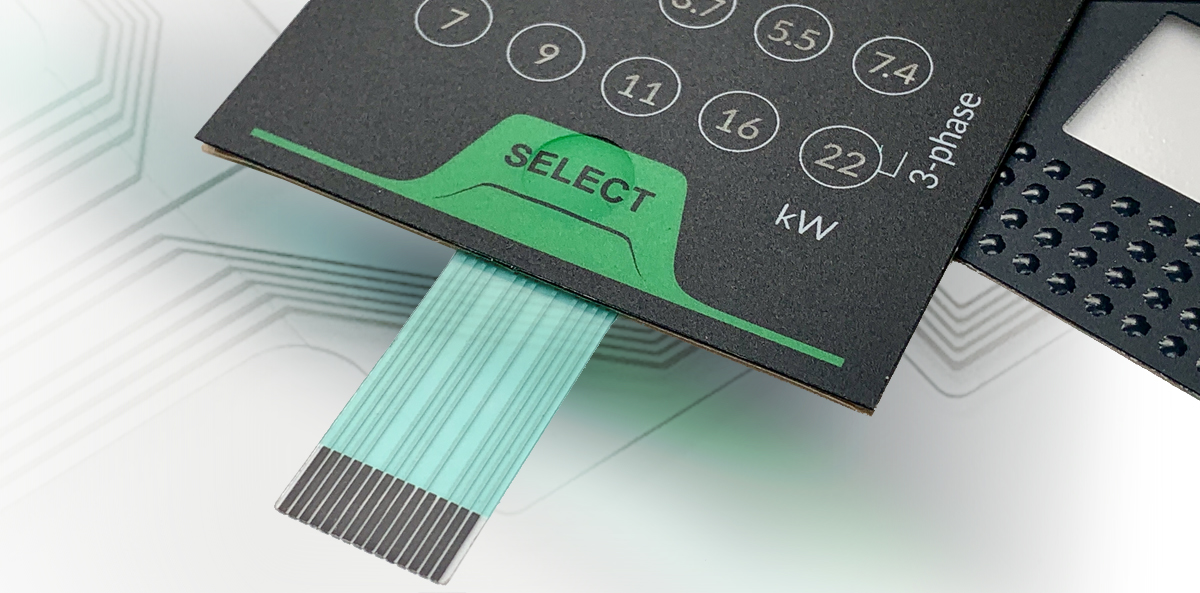

The unique properties of screen printing have made it the most effective method for producing control panels for electronic devices for years. Among its greatest advantages are the quality of […]