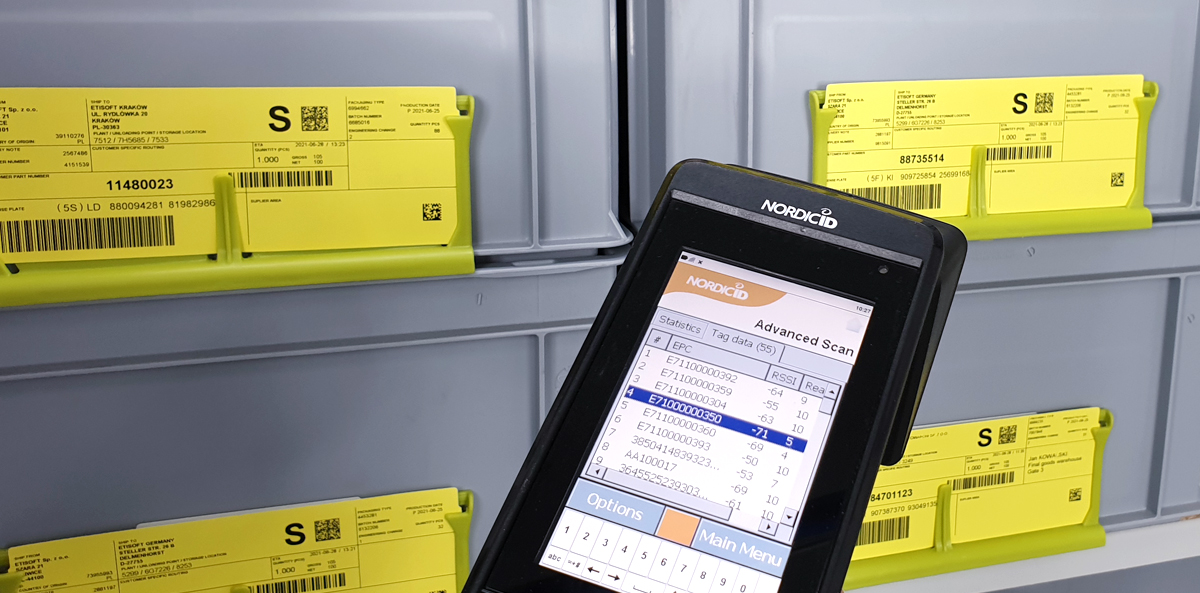

Logistics label GS1- consistent labelling system

Correct marking of consignments Perfect deliveries. Quickly, at the right time, in the right place, without mistakes. In addition, quick acceptance, registration in the system, etc. This is what we […]