Sew-in label printing for the textile industry. Learn about tried and tested solutions for cutting nylon or satin!

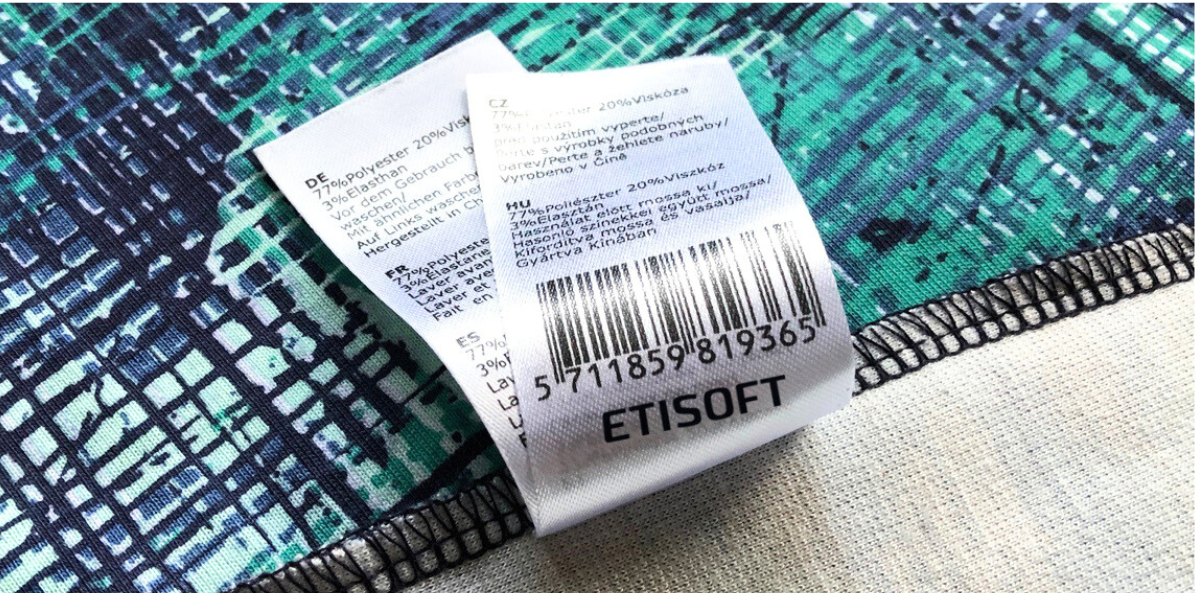

The textile industry is primarily associated with clothing products. However, this industry also includes all other products used in everyday life, such as towels, bedding, mattresses, curtains, and even cleaning cloths. All these products have one thing in common – they must contain instructions and pictograms on how to wash the item, as well as information on size and manufacturer. This information is printed on labels made of textiles such as satin or nylon. It is then sewn into the target product. The information is printed on one or both sides. Sew-in label printing can be done on all thermal transfer printers on the market. However, if the need arises to cut them, not all printers have the appropriate cutters for this purpose.

Sew-in label printing: from printing labels to cutting them, or what printer with a cutter to select

The printing of sew-in labels is already behind us – now it is time to start cutting them. Manufacturers of thermal transfer printers in most models do not prefer to cut these materials using a cutter fitted to the printer. Nevertheless, there are several models on the market, both desktop and industrial printers, for which manufacturers designed cutters for cutting such challenging materials. The challenge is that with both of these fabrics, the cutter blades tend to dull with frequent printing and cutting. In the case of satin, the cutter is very often not able to cut such a thick fabric. As for nylon, on the other hand, it can cut halfway or fray the trimmed edge. Moreover, even when the cutter is under warranty the manufacturers frequently disregard it. Therefore, special blades were developed to cut these materials, and the cutters are labeled as “Care label cutters.” The dedicated cutter comes with a manufacturer’s warranty.

A proven solution for cutting nylon

We would like to introduce you to the TE300 series desktop printer manufactured by TSC. The cutter proposed by the manufacturer for cutting such materials as sew-in labels is the most cost-effective solution on the market. Plus, it is covered by a 12-month warranty or 400,000 cuts, whichever comes first. This is the best assurance of the quality of the solution. The TSC TE300/310 printer comes in the following versions:

- TE300 thermal transfer printer with USB port

- TE310 thermal transfer printer with UDB port and Ethernet card.

The TE300/310 series printer, with a resolution of 300 DPI, features high print quality, which allows you to print high-quality labels with clear text and graphics. This is particularly significant for labels containing information pictograms and small descriptions. The printers are capable of printing at speeds of up to 5 inches per second, making it possible to process print jobs quickly. Both models feature 16 MB of Flash storage memory and 64 MB of SDRAM, allowing for greater data storage and faster processing. An additional advantage of this printer is a dedicated external label feeder, which allows rolls with a core diameter of 76 mm of continuous fabric to be installed and fed into the printer. It is an excellent solution for printing nylon sew-in labels in the textile industry.

How to solve the issue of nylon sticking to the thermal transfer ribbon

When printing nylon labels, electrical charges are generated, which cause the printed label to stick to the thermal transfer ribbon. Such a phenomenon makes the work and cutting of this material difficult. Of course, you can try to dissipate electric charges using brushes or wires. Unfortunately, in the long run, such a solution can make the work of the printer operator very unpleasant.

What kind of carbon paper for textiles? Read the expert’s advice!

Is there a way to do it? It is worth mentioning the solution that Etisoft engineers and programmers applied to the proprietary ETILABEL software for label printing. Our engineers together with programmers attempted to solve this issue with incredible results. We added a feature in ETILABEL software that eliminates the sticking of the material to the ribbon. As a result, you can successfully print a short series of labels without worrying about it.

Benefits of the TE300 series printer for cutting textiles:

- attractive price

- textile cutter

- comprehensive hardware solution (printer + cutter + feeder)

- compatibility with the proprietary ETILABEL software (label maker)

- manufacturer’s warranty on the cutter dedicated to textiles.

Summary

The TSC TE300/310 series desktop printer is a proven yet cost-effective solution for printing labels on textile materials. The 300 DPI resolution provides high-quality printing of labels with fine text and pictogram graphics. As a desktop printer, even when combined with an external stand for continuous materials, it does not take up much space at the workstation. Adding a dedicated cutter for textiles and using ETILABEL label maker provides a practical solution that fully meets the demand for printed sew-in labels. It is worth adding that this is a perfect solution for printing short runs.

Do you want to buy this set from one source? Are you interested in a label printers or ETILABEL software?