RFID jewelry tags – technology worth its weight in gold!

The jewelry industry combines luxury, precision and exceptional value of products – both emotional and material. Each ring, watch or necklace is not just an object, but often a work […]

The RFID identification label is used to identify finished goods, semi-finished goods, and components during production processes. The RFID system significantly accelerates and facilitates production traceability and product verification throughout the supply chain. That is why the automotive industry increasingly often introduces marking of components with RFID tags. RFID tags make it possible to store a big amount of data, and to add information at the subsequent production stage. Depending on the specificity of a product and its production, an RFID label can be applied to the product or placed inside it. The advantage of the RFID system is the possibility of reading data from many tags at the same time, from a long distance, from labels that are invisible to the eye, when the tag is placed inside the product under the housing.

Application

RFID labels in the form of a flag are designed for marking cable bundles, power, hydraulic and rubber cables in the automotive industry. They meet the requirements of VW and BMW concerns regarding the marking of components in RFID systems. The RFID label in the form of a flag is made of plastic that is resistant to accidental tearing, water, and high temperatures. It provides marking durability and safety of information stored in an RFID chip. The label with a flag where an RFID chip is placed is frequently applied at the beginning of the production process. In addition, identification data in the form of a bar code or 2D code can be printed on the white surface of the flag.

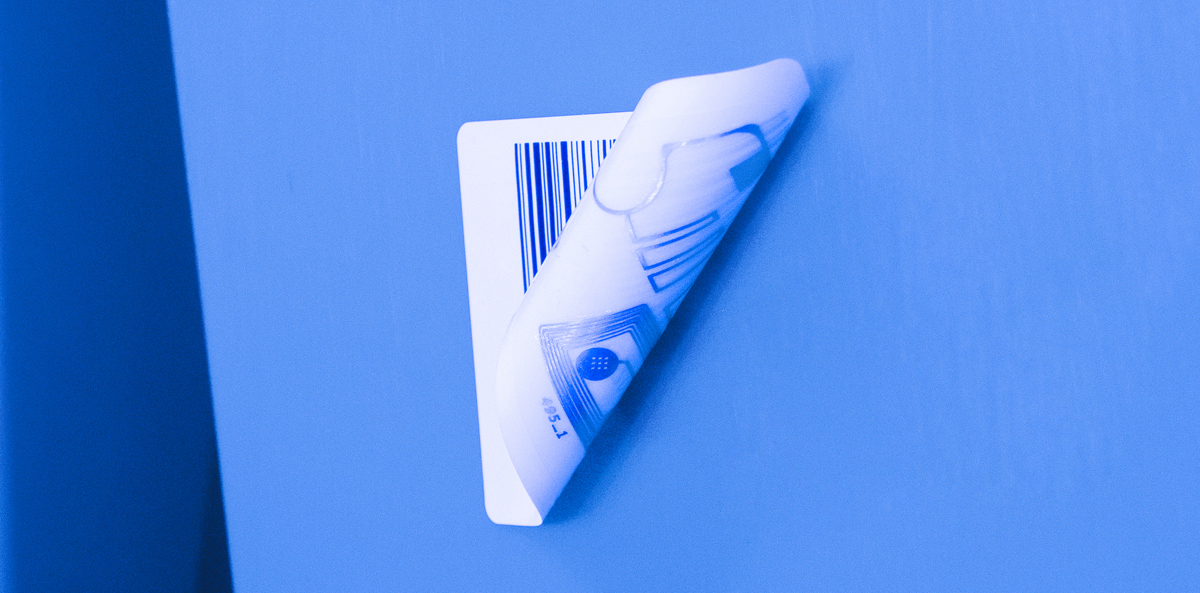

An RFID inlay is a chip with an antenna placed on a self-adhesive layer. The RFID inlays are most used in traceability systems for marking products and components. During production, the RFID inlay is placed inside the product. Thanks to that the chip is protected against damage and remains invisible to the eye, which is not an obstacle for the RFID reader. Such solutions are used in the automotive industry by manufacturers of car seats, headrests, electronic equipment, and home appliances. RFID identification labels enclosed under the housing, sewn into the components, make it possible to identify the component throughout the supply chain.

RFID self-adhesive labels are the most common solution used in production batch traceability systems. Identification data can be easily printed on the labels and thus data can be written to the chip memory using RFID printers. That is why RFID self-adhesive labels are most eagerly used for marking components in all branches of industry. The type of the label and adhesive layer is selected individually for the surface to which it is to be applied. Metal components are an exception since metal interferes with reading data from the chip. Special RFID on metal tags are dedicated for marking metal components with flat surface.

RFID tags are used in places where labels cannot be applied, e.g., wires, pipes. They are used to identify components during production. The tags are made of materials that are resistant to various conditions, dirt, and accidental tearing. White, smooth surface of the tag is prepared for printing identification data or a bar code. RFID tags can also be used for marking metal components since the RFID chip placed on the tag does not come into contact with the product surface.

The jewelry industry combines luxury, precision and exceptional value of products – both emotional and material. Each ring, watch or necklace is not just an object, but often a work […]

Due to the demands of the automotive and e-mobility industries (we wrote about them, among other things, here), also labels and tags must feature increased durability in unusual conditions that […]

RFID in the automotive industry The RFID (Radio Frequency Identification) technology is boldly making its way into more and more industries. The automotive industry is one of the industries which […]

You are implementing a solution based on RFID tags. Regardless of whether the impulse was the requirements of your business partners or your own initiative related, for example, to the […]

There are several reasons for implementing new solutions in a company. It is frequently the desire to improve existing processes or introduce automation, other times it is the need to […]

Author of graphics: Joanna Rawlik-Krupa Inquiry

For many years one of the problems relating to the implementation of RFID technology was application of tags to metal surfaces. Typical RFID markings in the form of standard RFID […]

Graphic designer: Joanna Rawlik-Krupa

While implementing RFID solutions sooner or later we face the question how to print and encode RFID labels. Although most of the top printer manufacturers have RFID devices in their […]

Popular clothing labels perform plenty of functions at each stage of the “life” of the product. From the end user’s perspective, the most important is the composition, size, and washing, […]

What is RFID technology? RFID (Radio Frequency Identification) technology, although it has been known and used for decades, still arouses a lot of emotions. Perhaps not even so much emotion […]

Managing transport items – why is it worth tackling this chaos? Almost every industry in its production plants uses returnable transport items. These are, among other things, containers, bottles and […]