Thermally conductive tape – effective and efficient heat transfer in electronics

Every electronic device generates heat that must be properly transferred in order to function in the right way. Inadequate thermal management in electronics may not only lead to damage to the device but also reduces the comfort of use. It has also influence on the performance of the given device. A common method of heat transfer is the application of thermally conductive pastes to components. In the following article, however, I am going to focus on an alternative solution, i.e., a thermally conductive tape.

Thermally conductive tape vs. paste – which material is better for technological process streamlining?

Heat transfer using a thermally conductive paste definitely has its advantages. However, its improper selection, depending on the material from which the heat sink is made, or the wrong method of application can result in inefficient heat transfer. Moreover, in the case of mass production, the application of the paste makes the technological process longer.

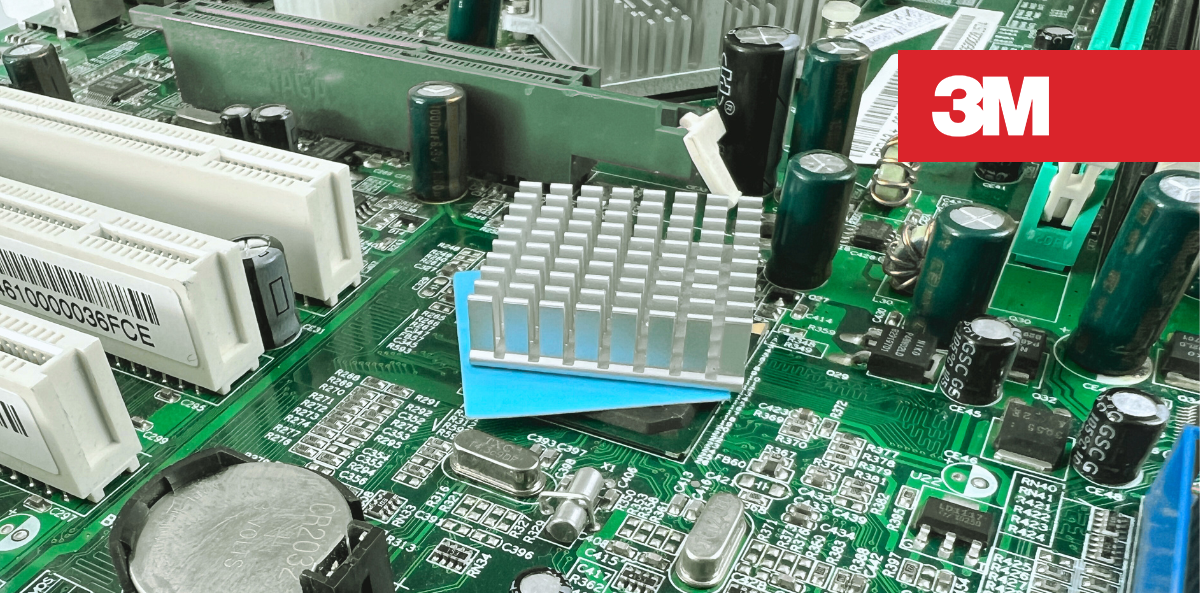

An alternative material which can successfully transfer heat and simultaneously streamline the technological process is a double-sided thermally conductive tape. Etisoft, as a preferred converter of 3M, has many years of experience in the field of materials and functional elements used – we recommend thermally conductive tapes and thermal pads. It is worth adding that we are also able to cut the roll to any width and manufacture ready-made die-cuts for a given application.

What are the features of 3M thermally conductive tapes?

3M™ 8810 and 3M™ 8926 thermal conductive tapes feature a high thermal conductivity coefficient. The higher the thermal conductivity coefficient, the better the conductivity.

It should be remembered, however, that the performance of the tape depends not only on the conductivity itself, but also on the application method. Contrary to pastes, self-adhesive thermally conductive tapes or thermal pads evenly adhere to the entire surface of the component tightly filling all micro-roughness. Precise adhesion to the surface provides efficient heat transfer to the heat sink. What distinguishes paste from thermally conductive tape is that the heat conductor does not need to be periodically replaced in the case of tape. An additional advantage is clean application without the need for additional tools.

Thanks to that, the workstation, and the device itself do not get dirty. Another advantage of a thermally conductive tape is its versatility. Thermally conductive tape and thermal pads feature double-sided adhesiveness which means that they successfully not only transfer heat, but also bond surfaces together. Additionally, they perform a full sealing function against moisture and dirt and absorb vibrations.

Advantages of a thermally conductive tape:

- good thermal conductivity

- adhesion to various surfaces

- dielectric insulation

- vibration damping

- sealing

- bonding of surfaces.

Application on PCBs – implementation for an electronics manufacturer

Some time ago, we were contacted by an electronics manufacturer with an enquiry about thermally conductive tape to be applied to PCBs. In this case, the customer wanted to receive a ready-made die-cut with specific dimensions so that the tape could be efficiently applied during production processes. With our technological capabilities we were able to implement this project by providing a double-sided thermally conductive tape in a form that made the production process as efficient as possible.

Examples of application:

- assembly of heat sinks

- heat conduction in integrated circuits

- heat transfer in PCBs

- LED lighting

- assembly of LCD panels

- COF connections.

If you are searching for a thermally conductive solution to your project, contact us!