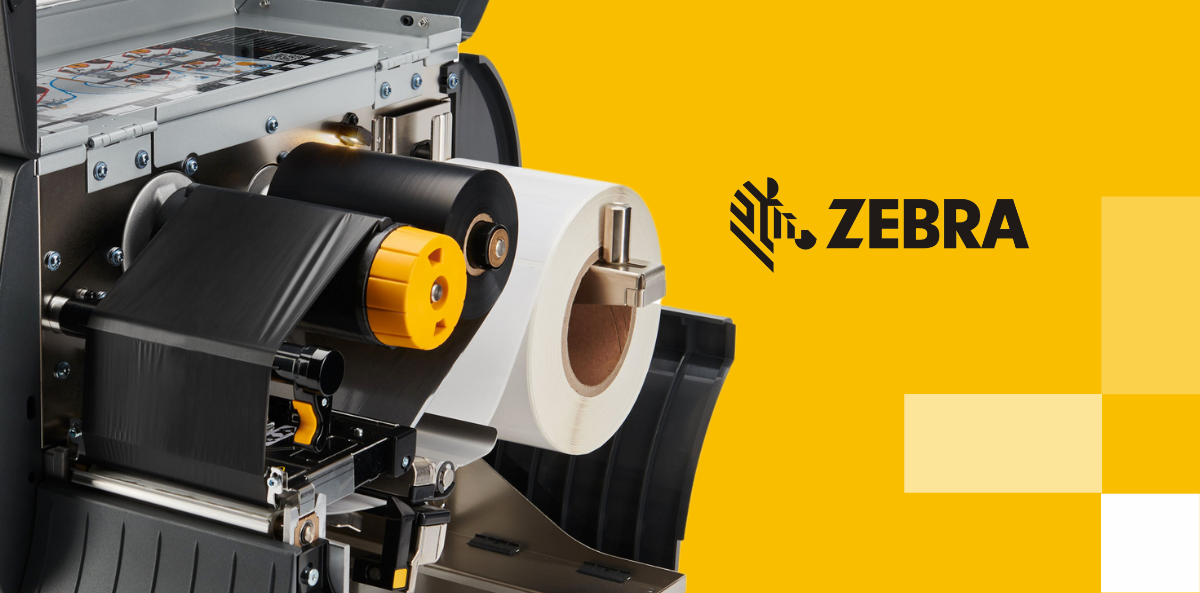

How to clean the printhead and care for your Zebra printer?

Keeping your label printer in good condition is essential to ensure its long life and trouble-free operation. Zebra devices are designed for ease of use, but like any professional equipment, they require regular cleaning of the head, platen roller and interior. Using the right consumables also affects their performance. Learn how to properly care for your Zebra label printers to avoid downtime and keep your printer running smoothly.

Cleaning the printhead and platen roller on a Zebra printer

The print head is responsible for printing on the label, while the pressure roller ensures even movement of the material under the head. Contaminants such as dust, adhesive residue and ribbon residue can build up on the aforementioned parts over time, causing a decrease in print quality and even accelerated wear and tear on the equipment. Routine cleaning routines will help maintain optimal print quality, extend the life of the device and avoid unnecessary failures.

- Cleaning the printhead

The printhead is the most important and very delicate component of any label printer that requires regular cleaning. It is best to use a soft, lint-free cloth soaked in isopropanol (Isopropyl alcohol, preferably with a concentration greater than 99.7%). Cleaning should be carried out every eight hours of operation or every time the belt is changed. Avoid touching the head with your bare fingers, as they may leave greasy marks on the printhead.

- Cleaning the platen roller

The pressure roller, which is located under the print head, is also exposed to the accumulation of dirt. Cleaning the pressure roller should be performed at the same time as cleaning the head, so that any dirt is not transferred to the printed label.

- Cleaning the material path

To get rid of dirt, dust, and other debris from the travel path, use compressed air or a small vacuum cleaner. Clean tracks and rollers ensure that labels move smoothly in the printer.

Labels for Zebra printers

Different types of labels and properly selected ribbons have a direct impact on the quality of printing and the durability of the print head. The use of materials in accordance with the manufacturer’s recommendations minimizes the risk of failure and reduces operating costs. Here are some tips on how to choose the best labels and ribbons for your Zebra printer to keep it up and running for a long time.

- Thermal label printing

Choose high-quality thermal labels for your Zebra thermal printers. Printing thermal labels – without the use of thermal transfer ribbon – causes the print head to wear out faster. Therefore, frequent cleaning and maintenance of the head is recommended.

- Printing thermal transfer labels

Labels for thermal transfer printing are coated with a special coating, which also allows the dye to stick to the surface of the label and protects the print head. Therefore, choose only labels from reputable manufacturers for printing on your Zebra thermal transfer printer.

- Linerless label printing

Linerless labels are an innovative solution that differs from traditional self-adhesive labels. Instead of labels on a siliconized backing, the entire roll consists only of a continuous layer of self-adhesive material. This solution is more environmentally friendly because they do not generate additional waste. Linerless labels have a surface coated with a special non-stick coating, which allows them not to stick to each other in a roll. However, using them requires an appropriate printer model, adapted to such material and frequent maintenance.

Thermal transfer ribbons for Zebra Printers

Each type of thermal transfer ribbon – wax, resin or wax-resin – has properties tailored to the type of labels and their applications. That’s why choosing the right way to get the best print quality without putting too much strain on the print head.

See what supplies you need for a Zebra printer

In addition, using a tape that is slightly wider than the width of the label itself is a protective strategy – it reduces head-to-material contact, which reduces friction and extends life. As a result, the head does not come into direct contact with the label surface and the liner, and is protected by a layer of thermo-conveyor tape, which effectively prevents premature wear.

High-quality ribbons also allow you to set a lower printing temperature, which is important for the long-term condition of the printhead. Too high a temperature leads to faster wear or even damage to the heating elements of the head, which in turn translates into poorer print quality and the need for expensive replacement.

Print parameter settings on Zebra printers

Appropriate adjustment of parameters such as printing temperature (blackness, density, intensity), head pressure, its balance for printers printing from the left side and printing speed allow you to avoid problems related to excessive head wear. Precise settings also extend printhead life and optimize costs, which is especially important in high-volume environments.

- Print temperature setting

Setting the right printing temperature affects the quality of prints, but also the wear of the printhead. While the low temperature protects the printhead from excessive overheating, it may not be sufficient to achieve optimal print quality. Therefore, the printing temperature should be adapted to the materials used, the type of ribbon and the printing speed.

- Performing self-tests of the head

If there are problems with printing labels, you should perform a self-test of the head, which will show the degree of its wear. This test ensures that the print is consistent across the entire width, or that the printhead has damaged filaments and needs to be replaced.

Zebra Printer Maintenance Services

Signing a service contract with an authorized service center is an investment that ensures uninterrupted operation of printers. Regular service checks and repairs keep printers running longer and more efficiently. Systematic inspections allow for early detection of faults before they cause more serious problems. Having a service contract gives you the added benefit of replacement devices for the duration of the repair, avoiding disruption to daily operations and eliminating the risk of long-term downtime.

Etisoft provides an authorized service for Zebra label printers and other Auto ID devices. Thanks to this cooperation, customers can count on comprehensive support and assistance at the highest level.

Are you interested in maintenance services for Zebra printers –