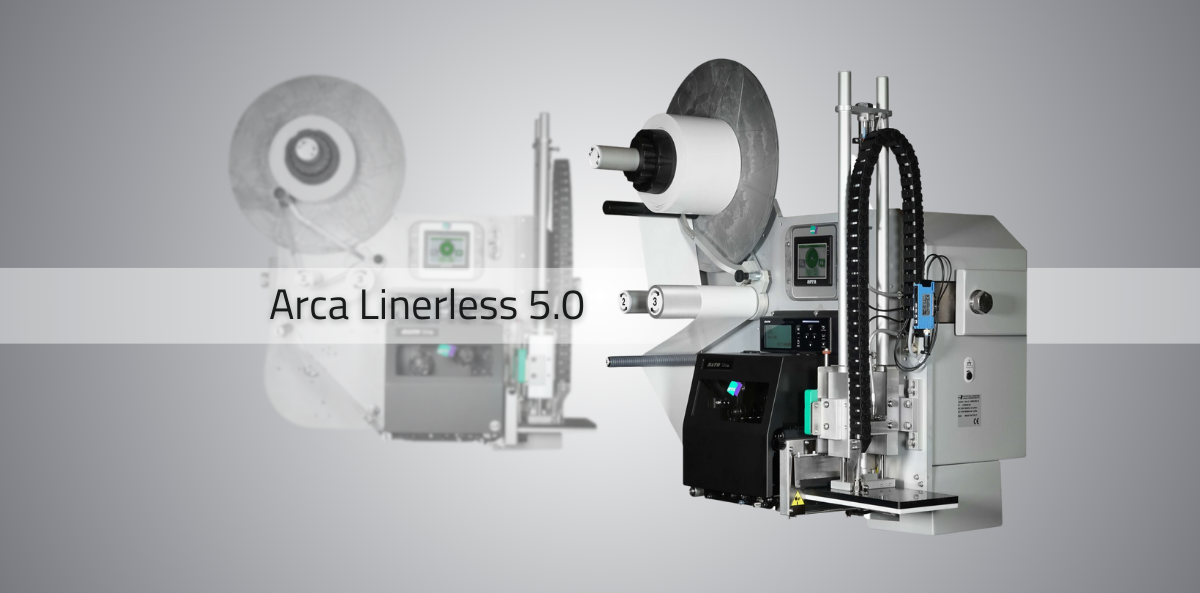

4 best high-end industrial label printers – reliability without compromise

In manufacturing and logistics environments, an industrial label printer is no longer just a peripheral device. It becomes a critical part of the process—one that determines operational continuity, product identification […]