Eco-friendly labels and sustainable development in long-term use applications

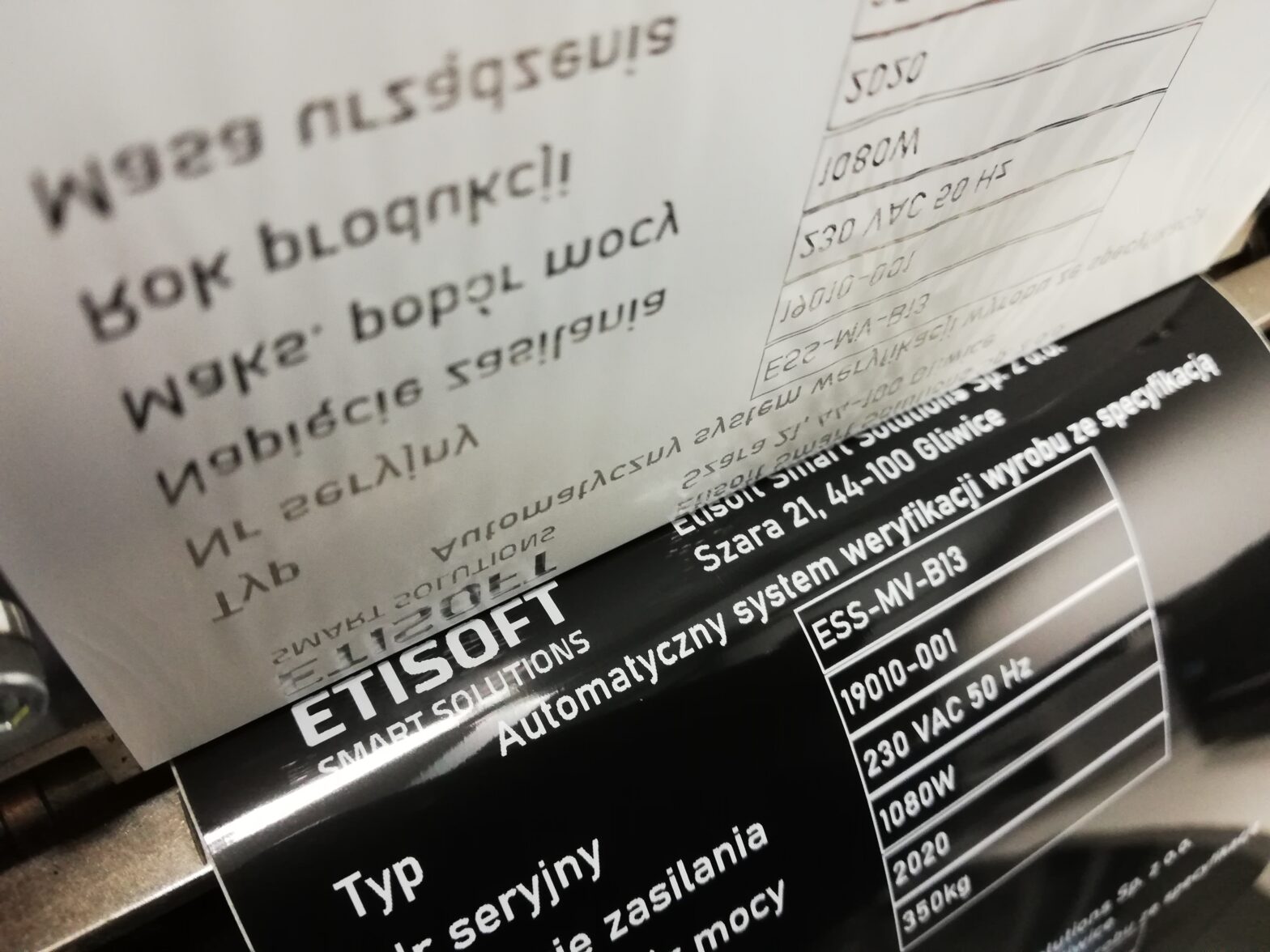

Sustainability has ceased to be a buzzword and has become a measurable goal for many industrial companies. Its challenges are increasingly affecting industries that use sustainable labels. These include the […]