AGV/AMR mobile robots. Learn 5 answers to key questions!

AGV/AMR mobile robots are modern solutions that have revolutionized internal logistics in many industries. Automation of material handling, using transport robots, has become an important part of modern manufacturing and warehouse processes. In this article you will read:

- What are mobile robots

- What types of forklifts they are

- Whether AGVs are different from AMR forklifts

- Where mobile robots are used

- Is it profitable and where to buy AGV/AMR forklifts

What are and how do mobile robots work?

Mobile robots are devices that can move autonomously or with minimal supervision around a designated area, performing transportation tasks. Through the use of advanced technologies such as artificial intelligence, sensors, cameras and navigation systems, they are able to precisely traverse production and warehouse halls transporting goods from point A to point B.

Automated or traditional warehouse – which to choose?

They operate based on pre-programmed routes. AGVs move by using magnetic strips or sensors to guide their movement. AMR robots, on the other hand, are more advanced in terms of navigation. They don’t need pre-set routes – they can analyze their surroundings on their own, avoid obstacles and adapt their route to the current situation in the environment.

What are the types of autonomous carts?

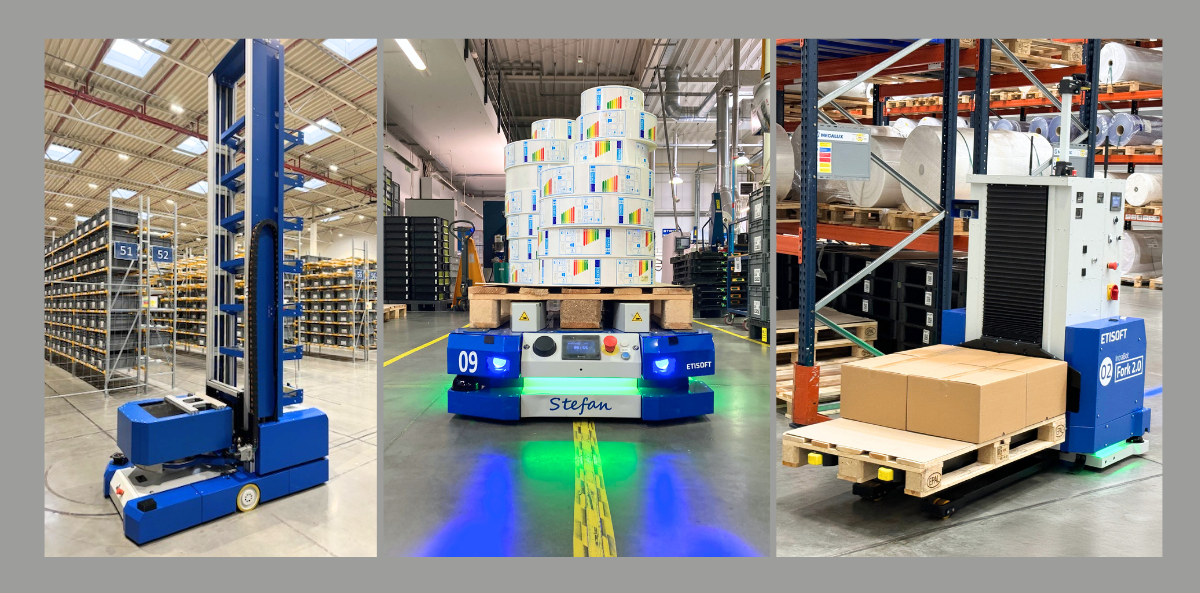

Autonomous carts can be divided according to the functions they perform and how they are used:

Transport trucks, which carry materials and goods between specific points. They can carry loads on top of each other as a “turtle,” tow wagons or hook up to storage garbage cans with wheels.

pallet trucks, which replace typical “pallet trucks,” are designed to lift and carry loads on pallets.

autonomous lift trucks, a version of forklifts equipped with lifting mechanisms that allows not only horizontal but also vertical transport (e.g., transporting pallets to racks)

specialized robots dedicated to more complex tasks, retrieving and depositing loads onto racks or conveyors.

Etisoft – a partner for industrial automation integrators. Check it out!

What are the differences between AGVs and AMRs?

The main difference between AGVs and AMR carts comes from the way they navigate and their flexibility in operation.

AGVs move along pre-programmed routes. They are precise, but require fixed infrastructure such as magnetic lines, sensors or guides to show them the way. They are ideal for environments where movement must be tightly controlled and repeatable.

AMR robots are more technologically advanced. They don’t need fixed routes because they can analyze the environment in real time. For example, they use LIDAR (Light Detection and Ranging) technology and a camera to map the space. This allows them to avoid obstacles and adapt their routes to the dynamically changing environment.

AMR robots are more flexible and versatile in operation, making them ideal for changing work environments where there may be human and other machine movement. AGVs, on the other hand, are better suited to fixed, repetitive transportation tasks.

Where AGV/AMR mobile robots are used

AGV/AMR systems are widely used in many industries, mainly where internal transportation of materials is necessary. They are most often used in:

- manufacturing industry – they transport raw materials, semi-finished and finished products between workstations, production lines and the warehouse

- warehouses, logistics and distribution centers – they streamline warehouse processes such as unloading, transporting goods, order picking

- hospitals – for distributing medicines, meals, picking up waste materials

- airports – for transporting luggage between halls, terminals and warehouses.

Is it worth it to buy an AGV/AMR robot?

AGV/AMRs reduce the need for forklift operators, which in turn reduces labor costs. In addition, they work without breaks, vacations or sick leave which increases the efficiency of warehouse processes and company productivity. The fleet of robots heterogeneously works 3 shifts, 24 hours a day, 7 days a week with the same efficiency.

The cost of purchasing an AGV/AMR robot and management system may seem high, but such an investment pays off in the long run. This is mainly due to labor savings, fewer accidents and damage to goods, and increased process efficiency. Moreover, AGV/AMR robots are more precise than traditional forklifts, which minimizes the risk of errors and accidents.

Where to buy AGV/AMR mobile robots?

Buying robots together with a management system requires a cost-effectiveness analysis of the implementation beforehand. That’s why it’s worth working with reputable suppliers and manufacturers that offer not only the mobile devices themselves, but also consulting services and comprehensive technical support. Etisoft offers professional intralogistics systems, designed and manufactured by the Polish company Etisoft Smart Solutions. The company also conducts pre-implementation analyses to help decide on implementation, presents the level of investment required, as well as the benefits to the customer after the introduction of a robotic intralogistics system.

Autonomous mobile robots. Use pre-implementation analysis!

ESS also offers long-term rental of AGV/AMR trucks, which can be an attractive alternative for companies that are not ready to make large one-time investments.