RFID labels – a new investment worth a million euros! Learn the 7 benefits of cooperating with Etisoft

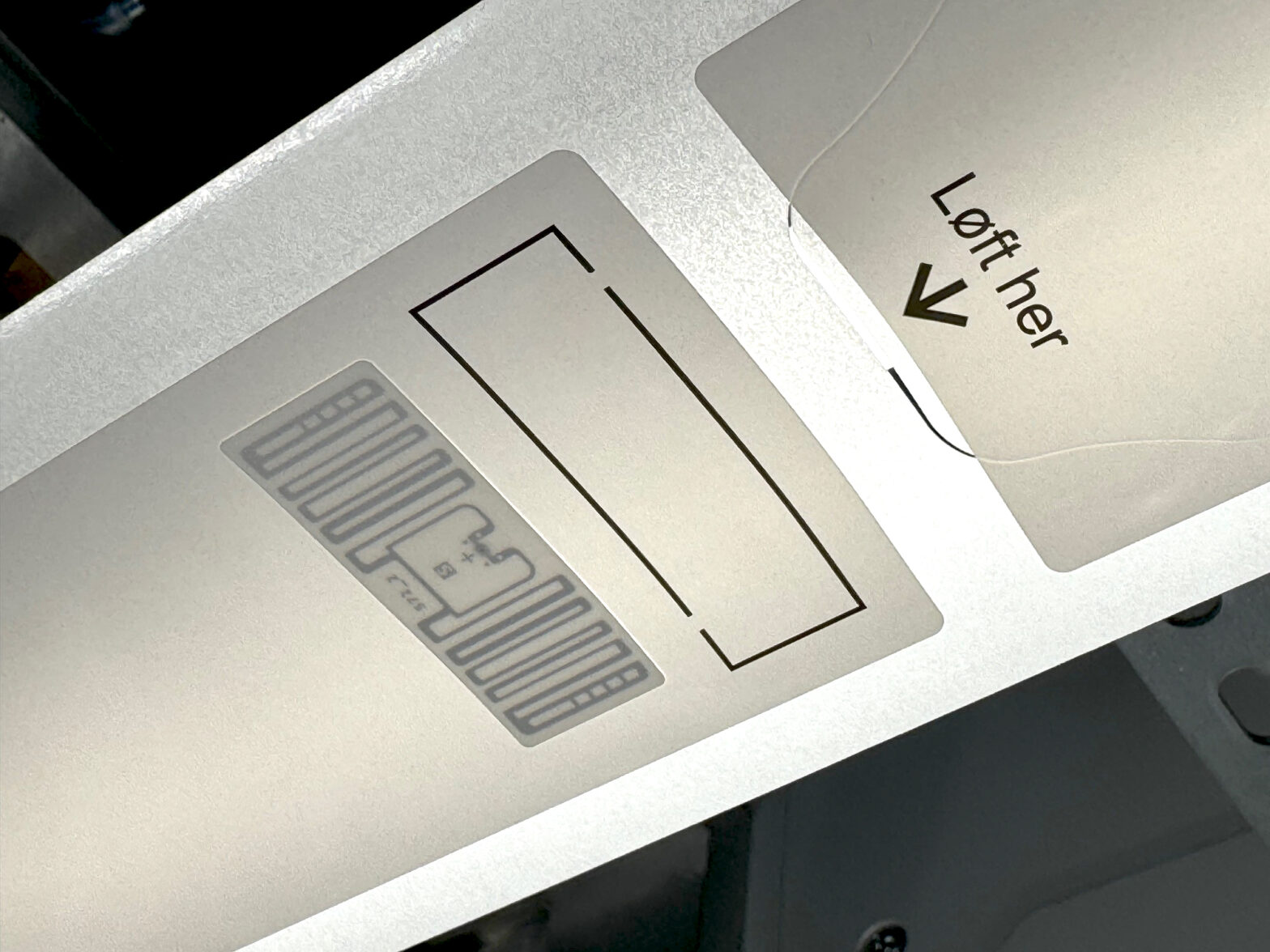

RFID (Radio-Frequency Identification) technology plays a key role in automating identification and product tracking processes, allowing for fast and precise reading of data from labels using radio frequency. Understanding the needs of the market and drawing on our previous experience as a supplier and manufacturer of RFID labels and markings, in 2022 Etisoft’s Management Board made a strategic decision to allocate resources to purchase advanced machines from Mühlbauer and to establish a new department within the organization that specializes in RFID label manufacturing.

RFID labels and two new lines for their manufacturing. Why Mühlbauer?

Deciding on a production machinery supplier is never easy. The experience that we had gained previously in manufacturing RFID labels using our equipment greatly facilitated our choice. We knew what we were searching for and what we wanted to manufacture with the new machines. We visited several industry events and our partners, suppliers, and RFID tag manufacturers. The capabilities of the machines that we could also see in manufacturing conditions and the recommendations of our partners made it easier to decide on the selection of this particular supplier. Although eventually, the decision was not easy anyway due to the possible machine configuration, in a relatively short time we were able to order and install two new lines in Gliwice:

- RFID label production line

- Line for RFID label customization.

A representative of one of our RFID tag suppliers later said during a visit to Gliwice, ‘You have bought Mercedes-class RFID manufacturing machines – congratulations!’ This only reinforced our decision.

Where and ‘with what’ do we manufacture RFID labels? The scope of investment:

- RFID label manufacturing department

Within the scope of investing in modern machinery, we adapted the existing warehouse hall to the needs of the new RFID label manufacturing department. The decision resulted from the need to ensure optimal working conditions for the new Mühlbauer machines and to use the new technology effectively. The modernization of the infrastructure carried out included adjusting the space, improving ventilation and lighting, and providing an appropriate power supply.

RFID basics, or rather facts and myths about RFID

2. The line for manufacturing (converting) RFID labels. Main features:

- Efficiency: The machine provides high production capacity, making it possible to process various materials quickly.

- Precision: With advanced technology, the machine provides precise cutting of labels of various shapes and sizes while maintaining the position of the antenna relative to the label edge.

- Flexibility: The possibility of using different face materials and adhesives, as well as RFID tags operating in UHF and HF (NFC) technology.

- Verification and quality: Sensors at each section of the machine and a system for verifying the correct reading of the RFID tag provide the proper and consistent quality of each RFID label.

3. The line for RFID label customization. Main capabilities:

- Encoding: Encoding RFID labels with high efficiency based on the scanned code or database,

- Printing: The technology applied provides high print resistance,

- Verification: Each label goes through a verification process of the print and information encoded in the RFID tag.

A solid foundation is the key to manufacturing RFID labels for many industries

Our extensive experience gained from manufacturing traditional labels and adhesive materials provides a solid foundation for our involvement in RFID label manufacturing. The acquired skills and knowledge of our technologists and machine operators allowed us to quickly master the new production technology. This enables us to effectively use new machines for manufacturing RFID labels so that our offer is not limited to the basic solutions provided by other suppliers. Having been a label supplier for many years, we have been able to explore the diversity of industry needs, understand the differences in requirements for label materials, and utilize them in RFID tag manufacturing. Depending on the specifics and application, Etisoft uses a wide range of label face materials and adhesives, making it possible to adapt RFID labels to various surfaces and operating conditions. With this flexibility, our RFID labels can be used in many industries and areas. We manufacture and offer RFID labels for:

- textile industry

- food manufacturers

- automotive industry – VDA-compliant

- retail industry, compliant with the requirements of retail chains

- logistics and warehousing.

And also for:

- inventory

- production tracking

- and RFID labels for reusable crates.

Why should you order RFID tags from Etisoft?

We pride ourselves on:

- a modern machinery park

- a separate RFID label manufacturing department

- our own laboratory and R&D department which allow us to select the best solutions

- experienced machine operators

- a wide range of materials for label manufacturing

- collaboration with renowned RFID tag suppliers

- a comprehensive offer.

We are confident that deploying advanced Mühlbauer machines for RFID label manufacturing is a milestone in Etisoft’s development. With these innovative solutions, we can meet the RFID label needs of our customers in various industries. The investment opens up plenty of new opportunities for our business partners.