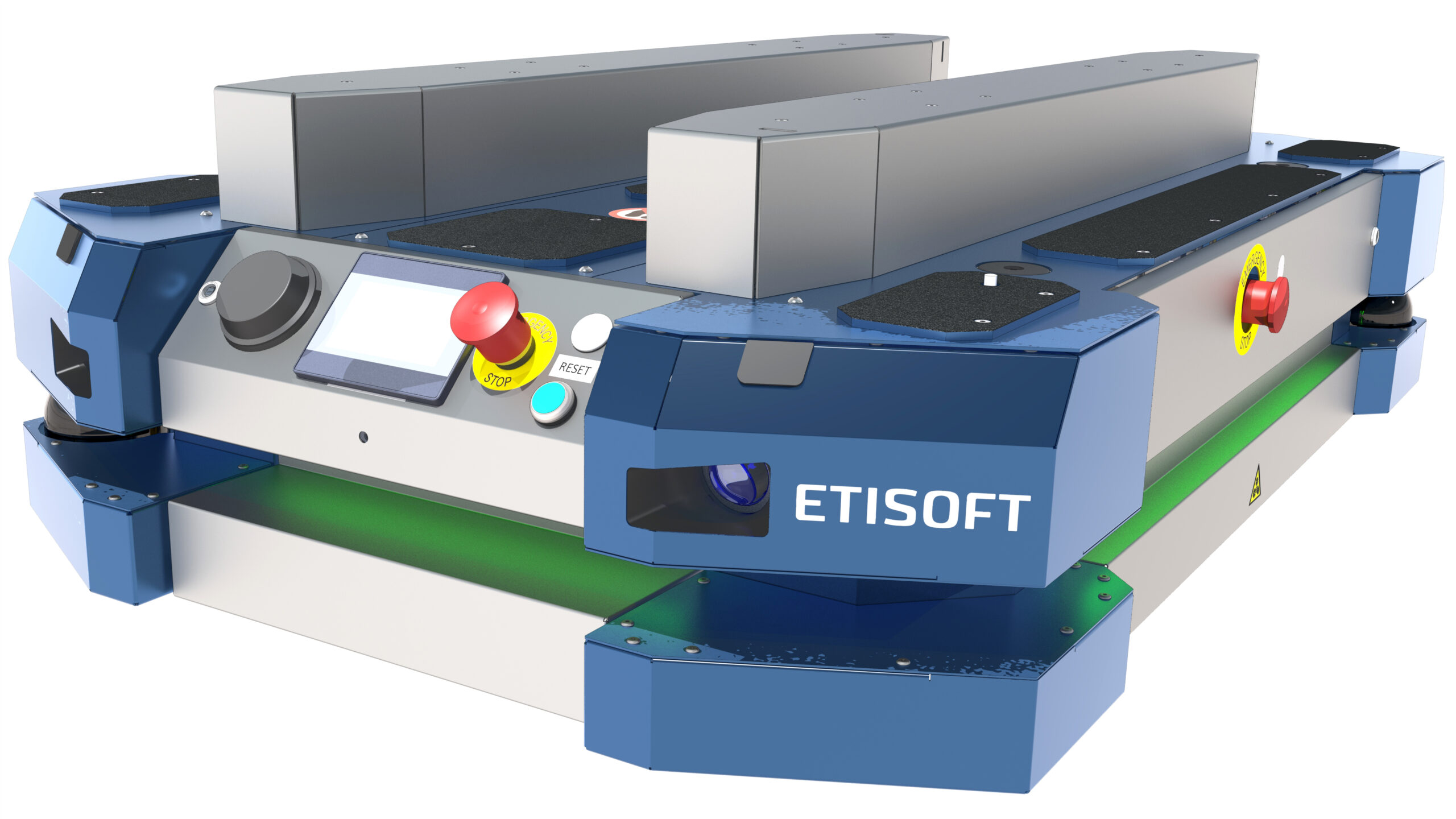

From labels to Industry 4.0: how mobile AGV robots work with labels in a smart warehouse

From labels to Industry 4.0 – isn’t Etisoft’s range of products too broad? “From labels to Industry 4.0” is not just a slogan, but our vision – showing how a […]